Arrival

Arrival is on a mission to radically change the design and production of electric vehicles; developing new technologies to build beautiful, functional, affordable and sustainable products.

Role

My role in the business had two parts: designing and building prototypes to support product development, and co-running our London workshop. July 2021 - Nov 2023. 2 years 5 months (Recently Redundant)

My duties as a prototype engineer included:

Build a range of prototypes requested from multiple departments

Create 1:1 scale models

Manufacture parts for prototype vehicles

Optimise builds by considering time, cost and purpose

Provide fast, iterative design development for designers

Design and build aluminium frame test rigs

Design and modify parts with CAD

Create product models with representative CMF

Integrate electrical components into prototypes

Support build requests from early concept to vehicle production

Work independently and within small teams

Manage workshop equipment use

Offer impromptu problem-solving to colleagues

Project manage individual and group tasks

My duties as a workshop manager included:

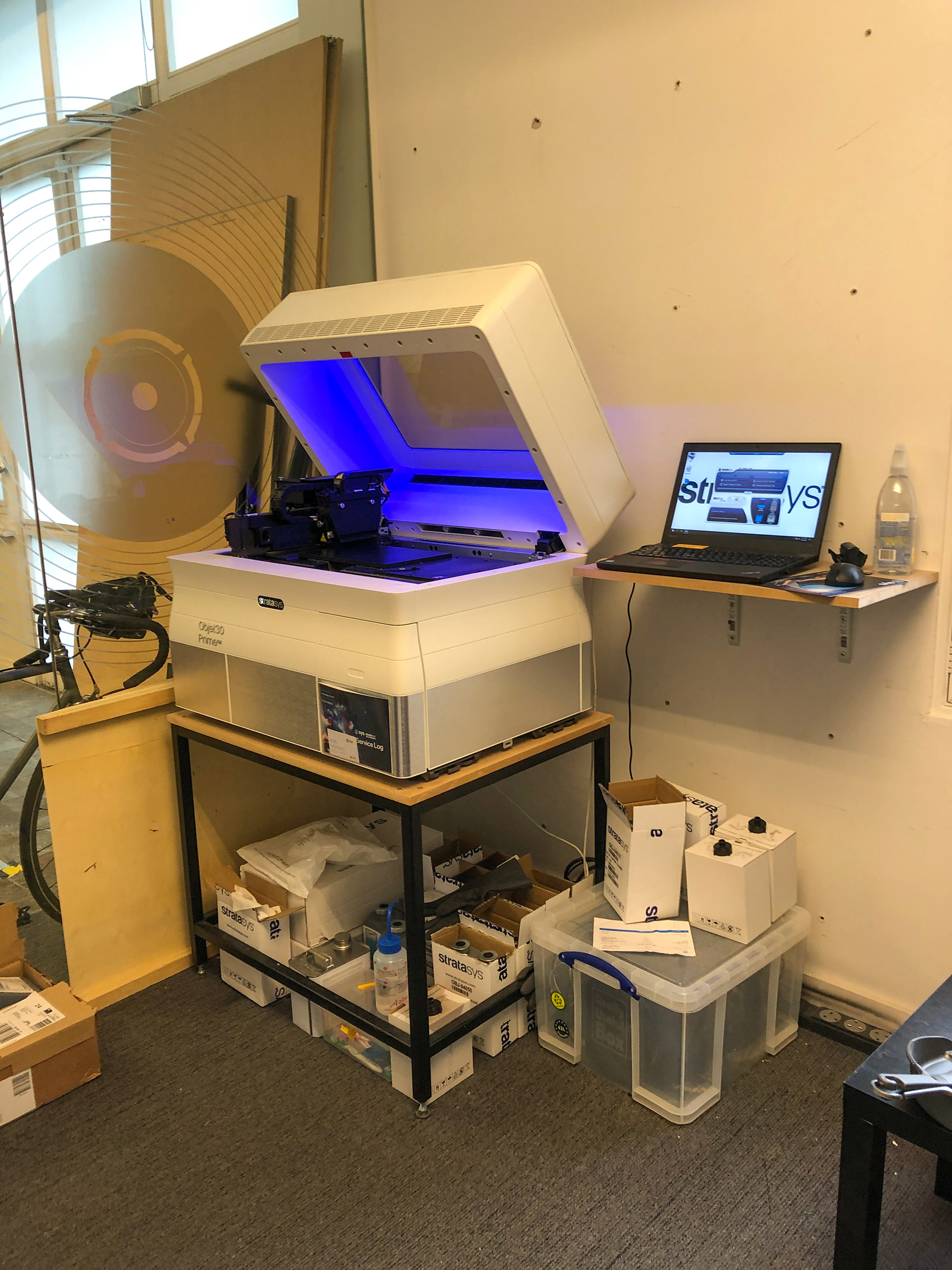

Advanced 3D printer operation - FDM and PolyJet

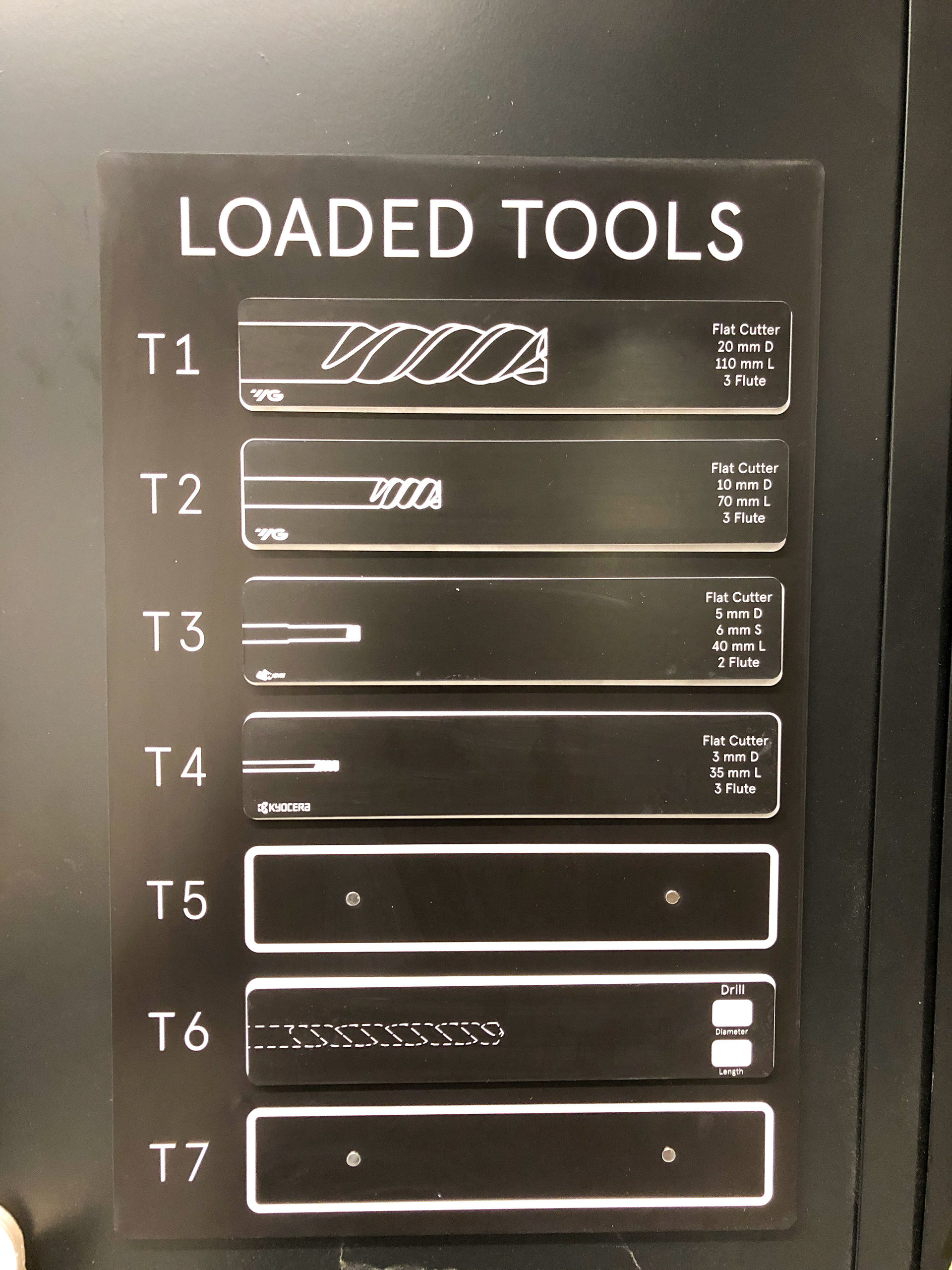

3-axis CNC programming and operation

Ensuring a safe place to work

Running workshop inductions and equipment training

Being a knowledge base to support workshop users

Ordering stock and consumables

Project timeline planning

Designing and setting up a new workshop using Arrival brand principles

Tailoring our Atlassian JIRA project to suit the specific needs of our small team

Conducting machine maintenance

Creating spreadsheets for cost analysis and projection

Past Projects

Van Interior Model 1:1 (Details Redacted)

Created this high-fidelity model used to visualise final design surface data and simulate user interactions within the vehicle. Contributed to the project planning, CAD, building, painting and assembly.

Requirements: Accurate visual representation of interior surfaces, CMF (Colour, Material & Finish) where possible, HMI (Human-Machine Interface) features integrated where possible, AR/VR compatible

Use Cases: Attributes review/sign-off, Pro-active fault finding, Executive interior design sign-off, Customer sign-off, Marketing/communication tool, CMF (Colour, Material & Finish) presentation tool

Making: The frame was designed in CAD and built from aluminium extrusion. I transformed designers’ surface data into a 3d solid and built up to fit around the frame. These elements were CNC’d (externally), painted (internally) to mimic CMF, and then assembled.

Van Concept Models (Details Redacted)

Created a series of 1:8 scale models for the Industrial design team. These models were used to help sign off a design direction. I machined these using a 3 axis CNC, assembled, sanded and painted these models for a quick turnaround.

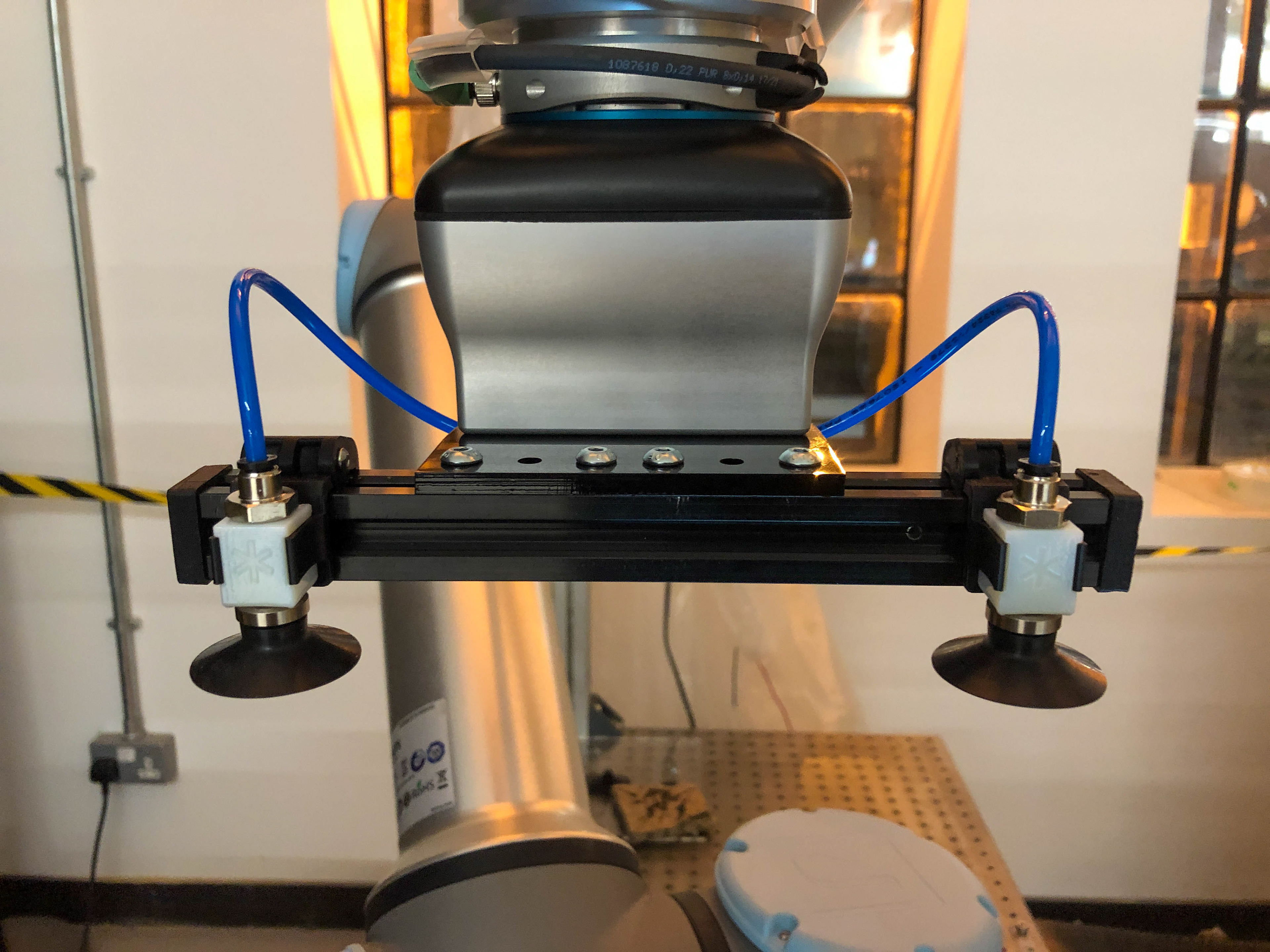

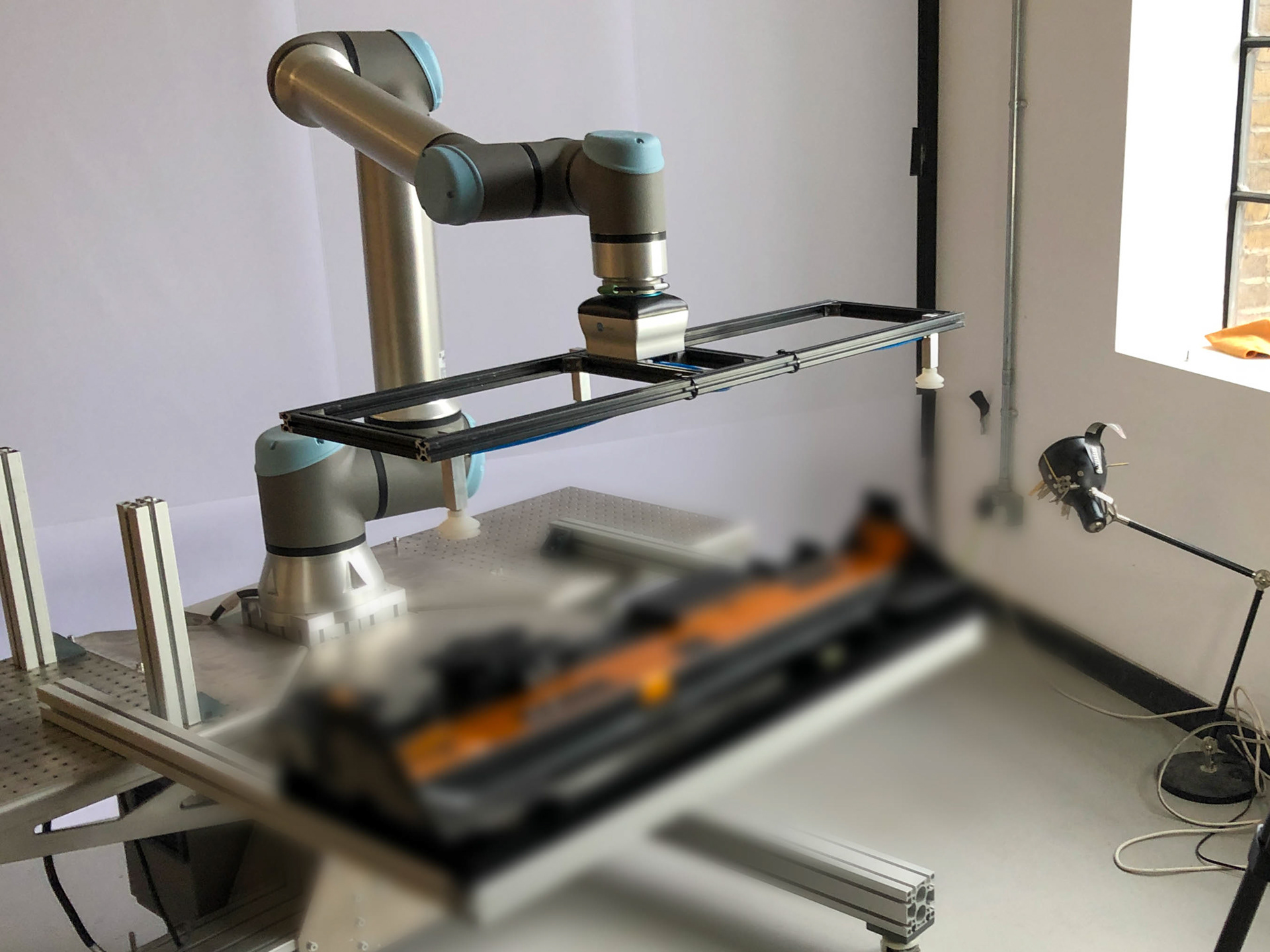

Suction Cup Clip

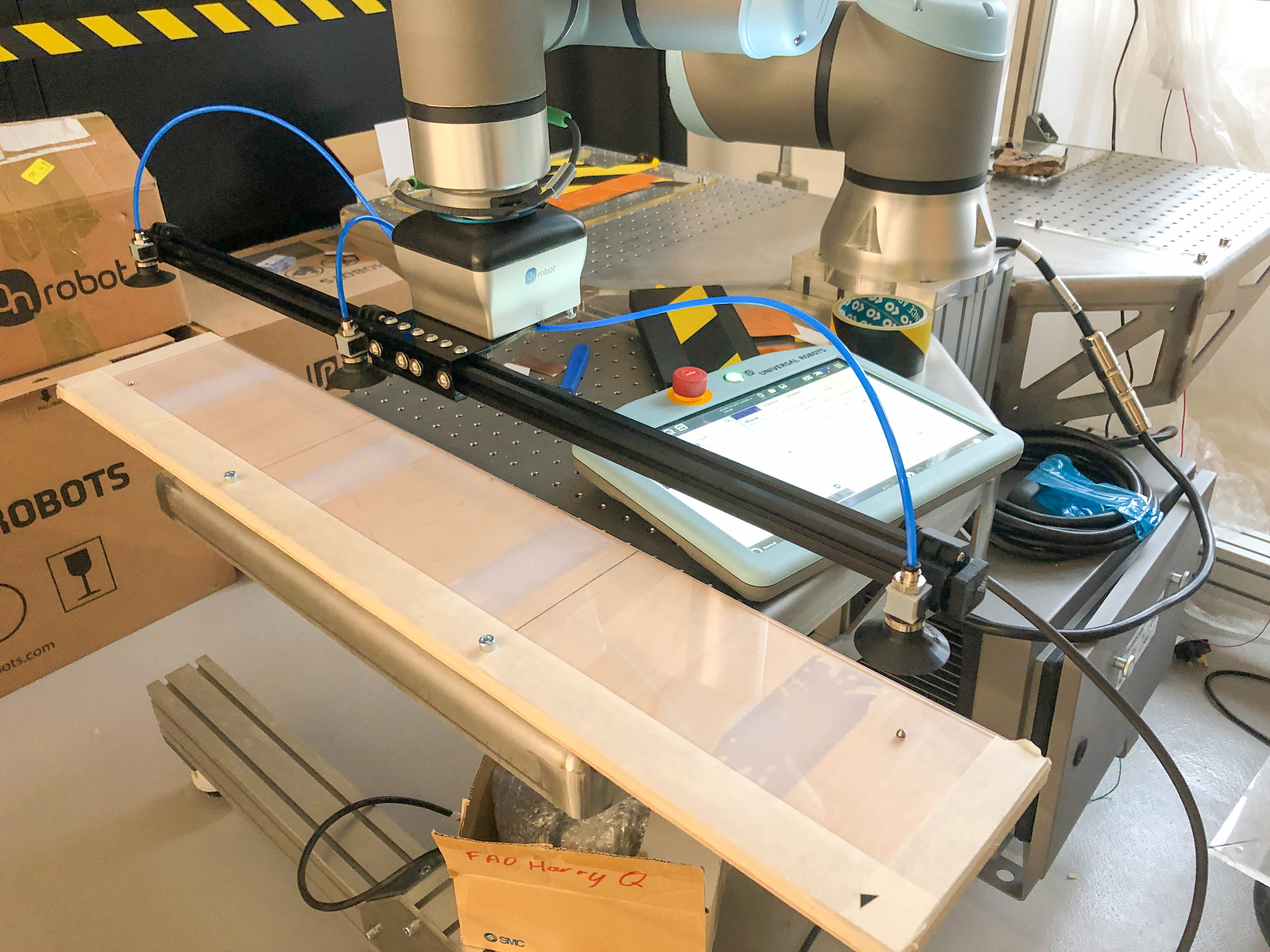

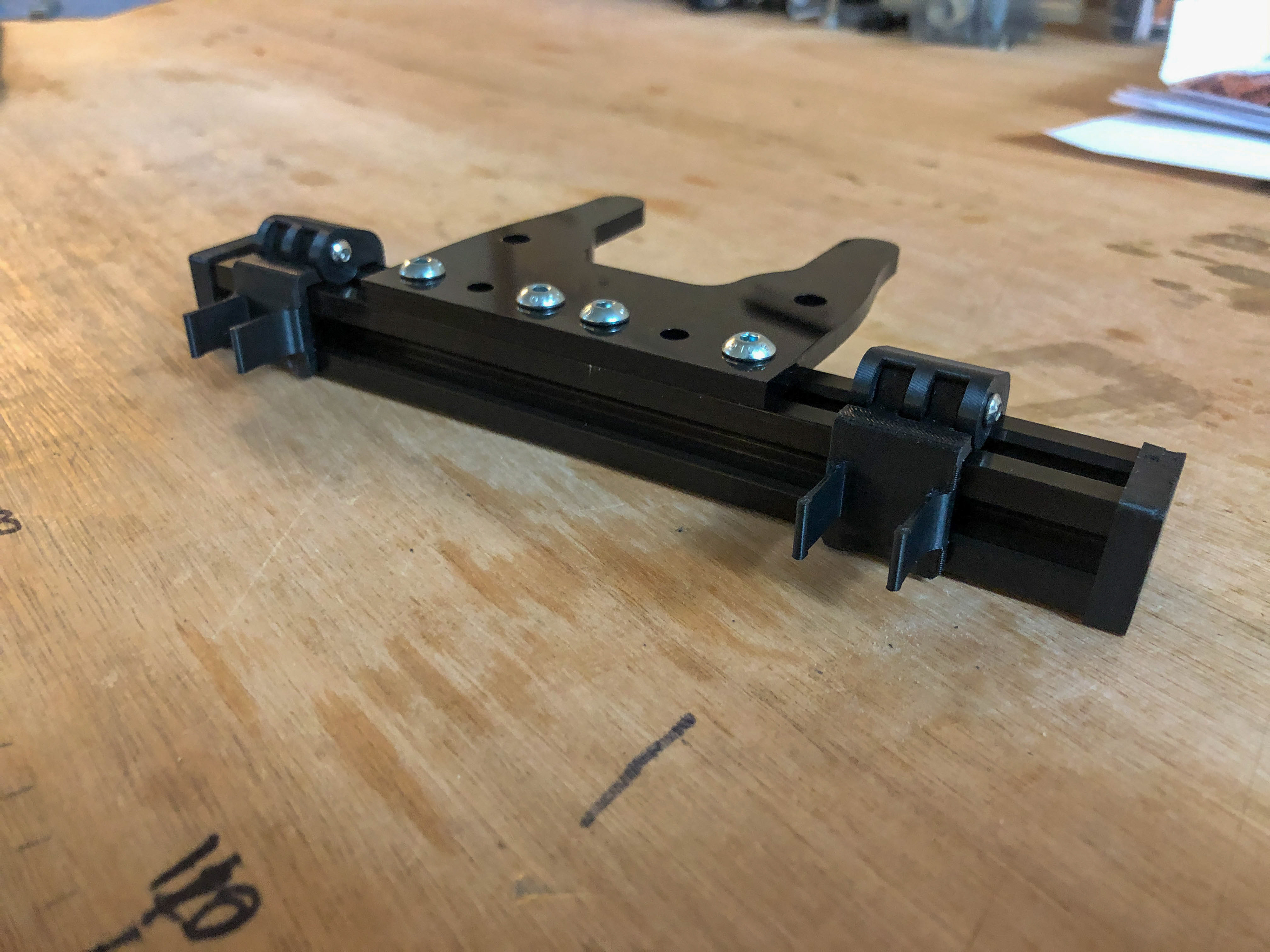

I was tasked to rebuild an outdated suction gripper attachment for a UR 10 robotic arm.

This project was related to a new method of vehicle door assembly being developed.

This was a fast development project of many iterations.

In response, I developed a quick-change testing rig to improve the static original.

In response, I developed a quick-change testing rig to improve the static original.

- Quickly swap different sized suction cups in and out

- CAM mechanism allows for very quick positioning of cup along the rig

- Cup module clip feature doubles as a safety mechanism. If the rig moves too close to a surface the cup pops off to prevent damage to a person, part or robot

- Tight tolerance ensured good friction grip

- CAM mechanism allows for very quick positioning of cup along the rig

- Cup module clip feature doubles as a safety mechanism. If the rig moves too close to a surface the cup pops off to prevent damage to a person, part or robot

- Tight tolerance ensured good friction grip

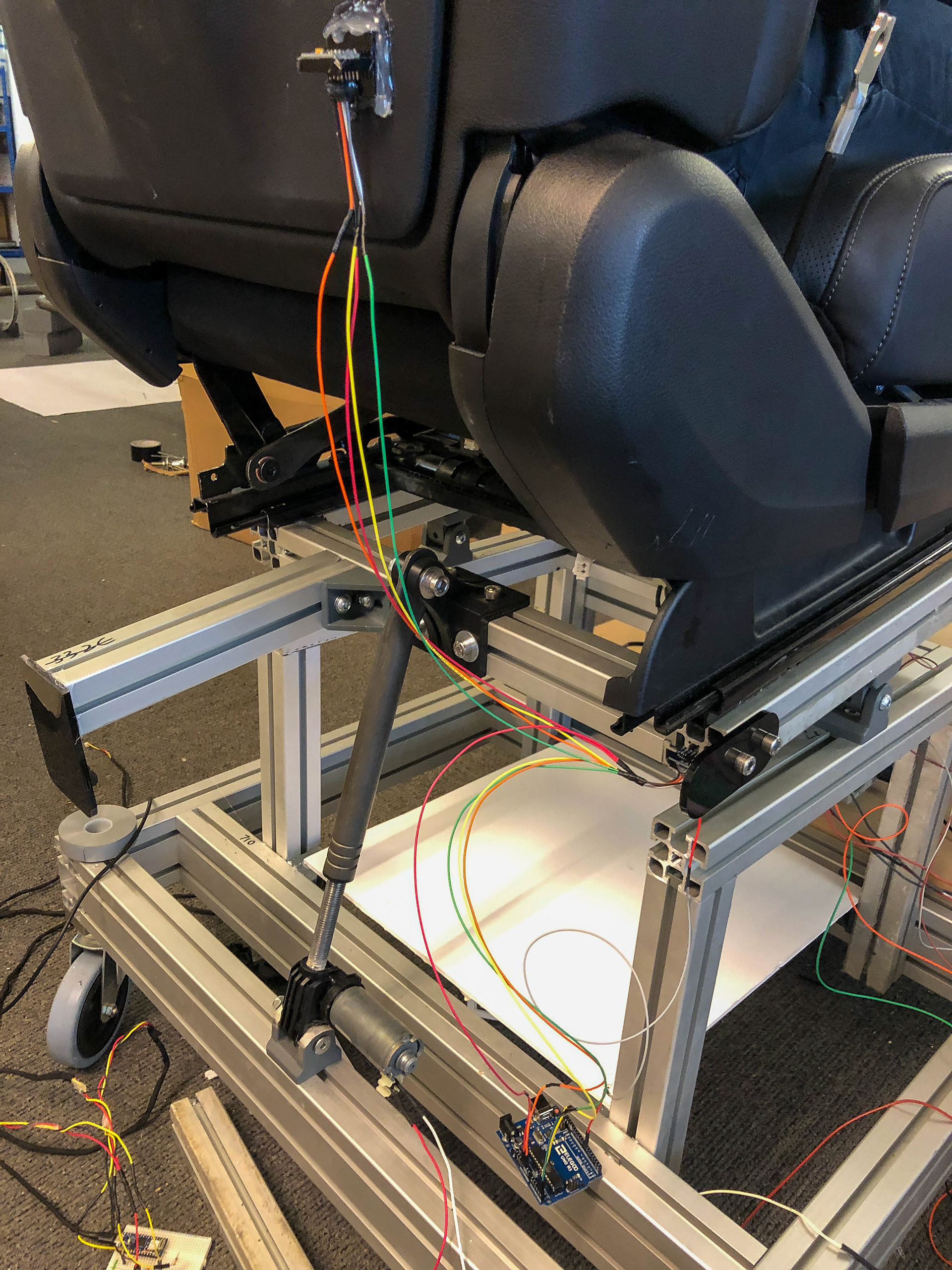

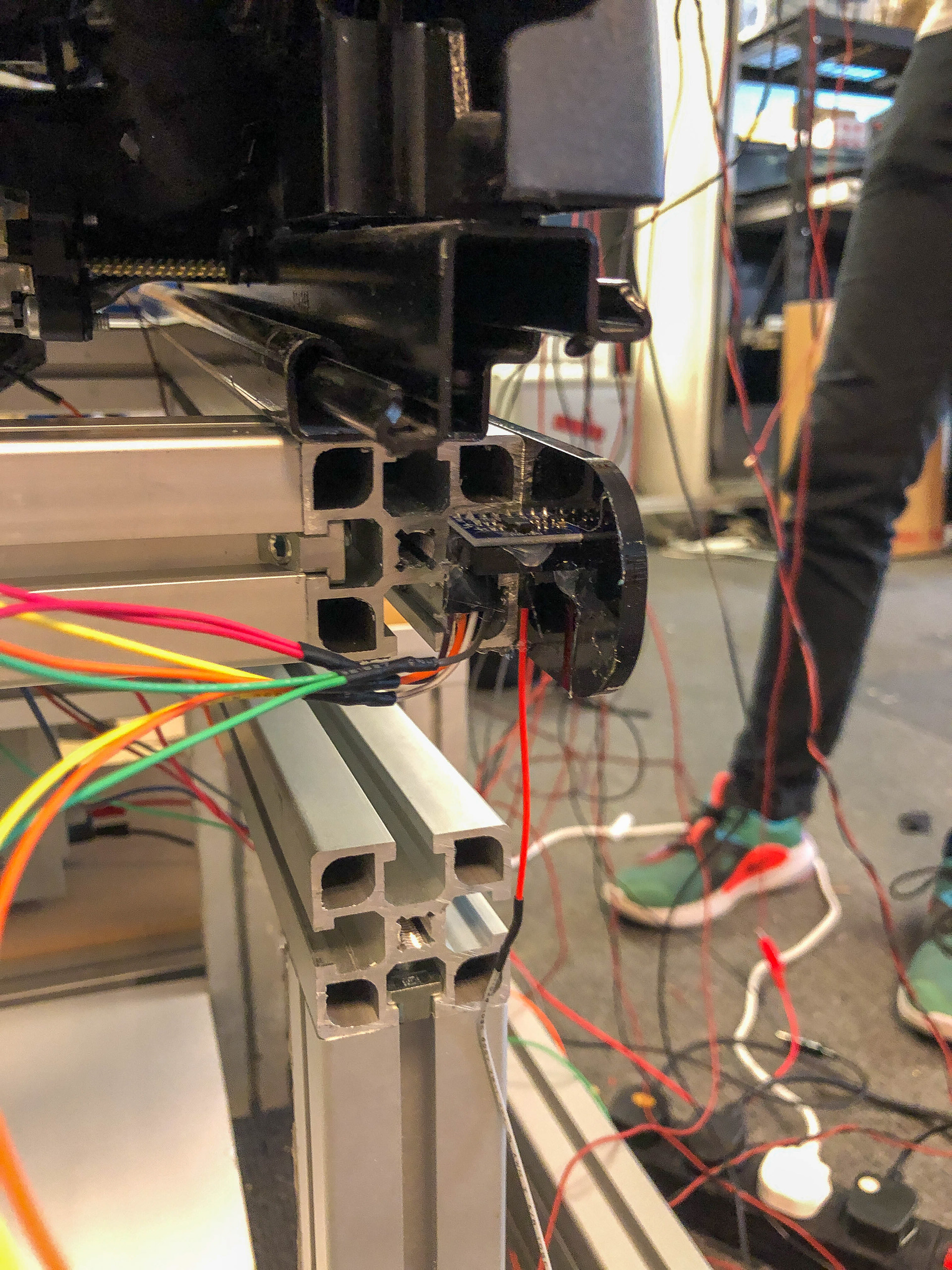

Safety seat - motorised seating position rig

The purpose of this team project was to create a seat rig to review the safety of users’ preferred seating position.

The user was given the ability to move the motorised seat in 5 different ways. To give that seating position a safety rating in real time we needed to measure the position of the seat against a known value.

I was given the task of making this system.

- I started by using a rotary encoder attached directly to the seat mechanism. This worked initially but was limited by the mounting position of the encoder

- In the final set up I opted for sensors that could take a measurement without being attached to a moving mechanism

- I used 2 accelerometers for lower and upper angle measurement and 2 optical sensors for seat height and position back or forwards

- An Arudino read measurements from these sensors, calculated the distance from a known position and outputted that to software to give the position a safety rating

- In the final set up I opted for sensors that could take a measurement without being attached to a moving mechanism

- I used 2 accelerometers for lower and upper angle measurement and 2 optical sensors for seat height and position back or forwards

- An Arudino read measurements from these sensors, calculated the distance from a known position and outputted that to software to give the position a safety rating

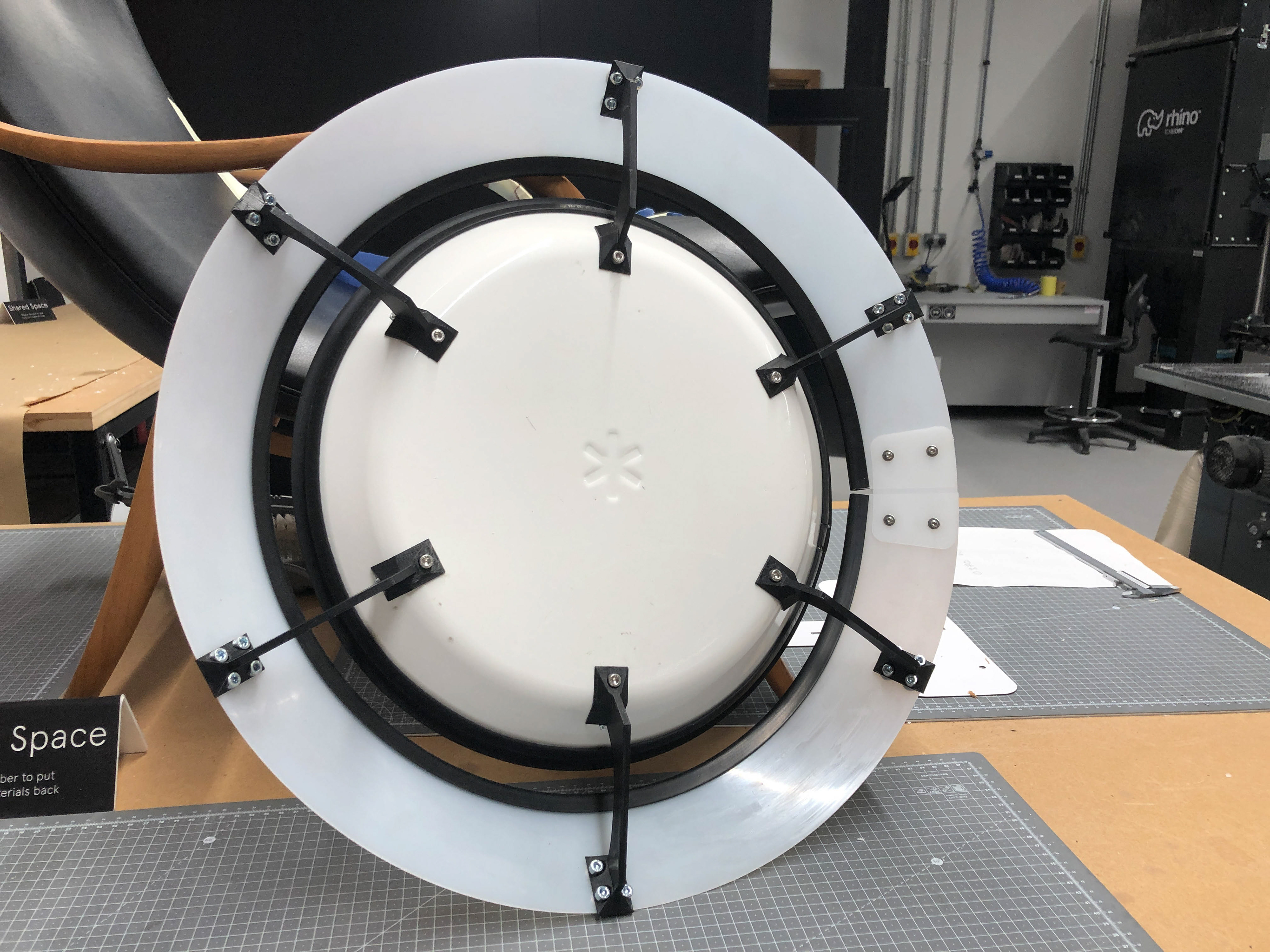

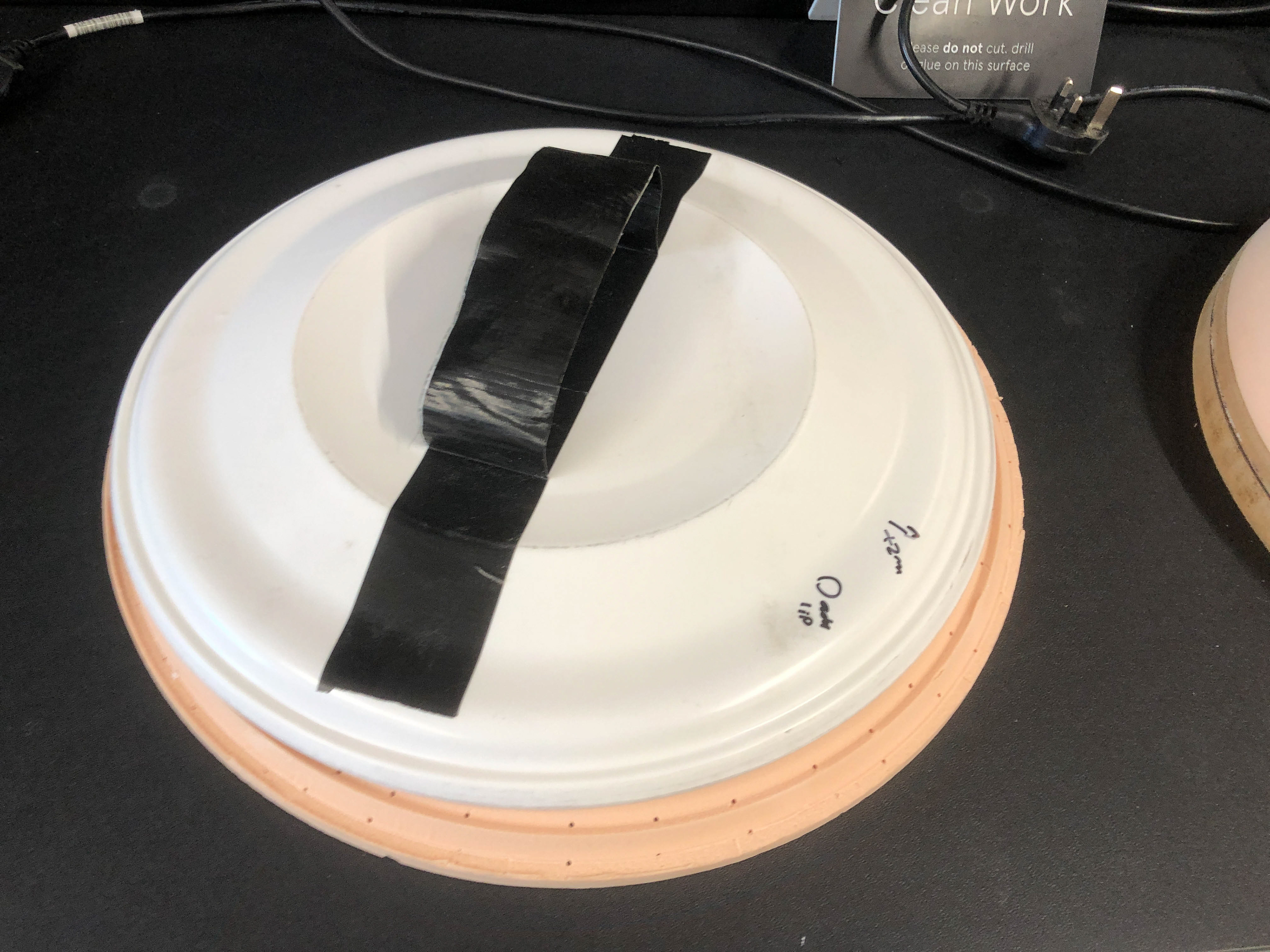

Wheel Rim Spray Paint Jig

We needed to create a jig to paint a thin silver rim onto a small batch of van wheels. We developed the design over many iterations experimenting with different seals, hub shapes and attachment mechanisms.

Workshop Improvements

Design, set up, and co-manage our 450m2 workshop to ensure it is safe, efficient, fulfils the needs of our R&D teams and is a pleasure to work in. The considered improvements I helped make to the space significantly improved the company’s ability to innovate efficiently, work collaboratively and increase our capabilities.

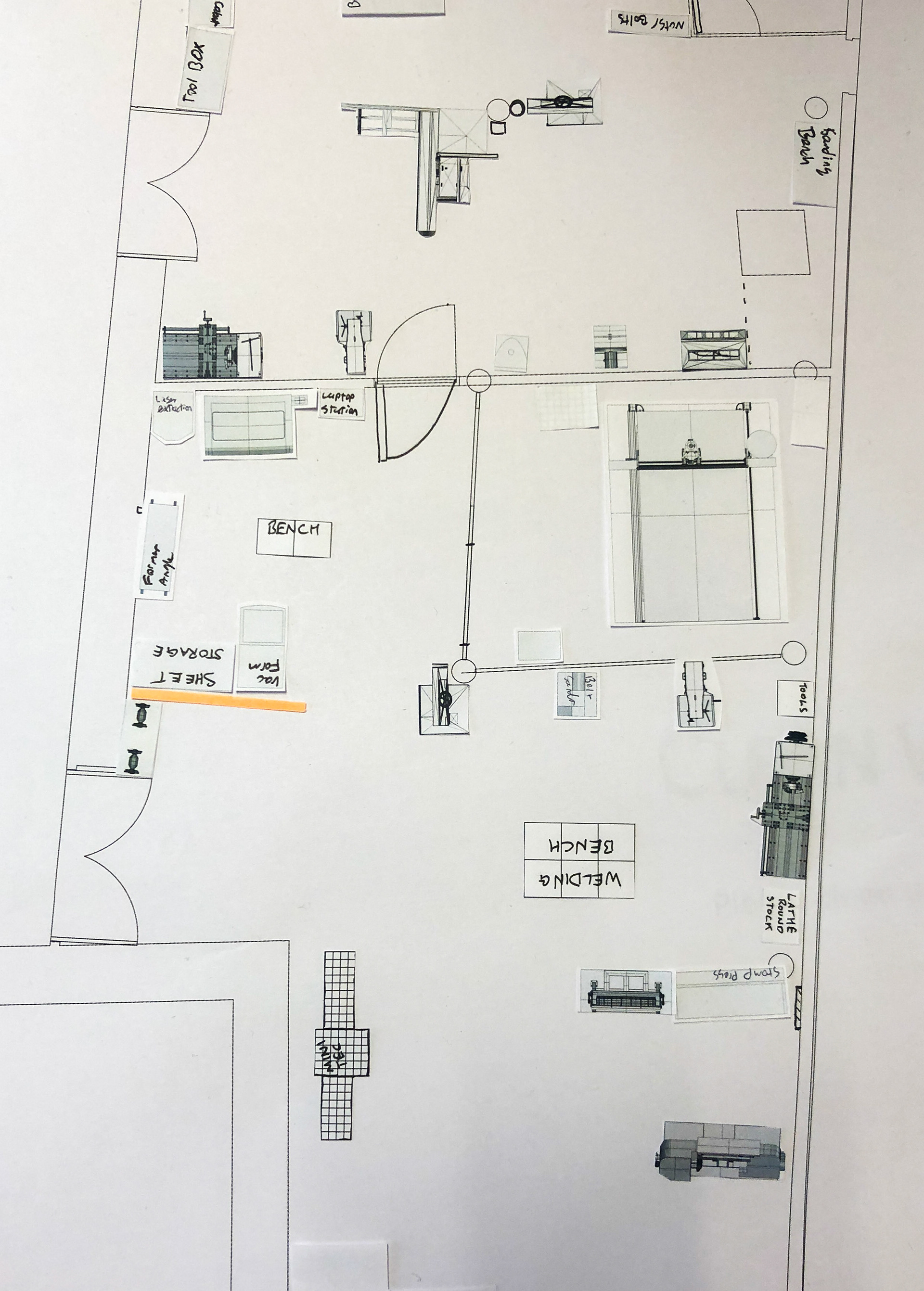

Layout

With attention to detail in mind, I proactively designed, set up and co-managed an exceptional company-bespoke workshop facility that stimulated faster and higher quality product development and encouraged designers to collaborate and engage practically with their design ideas.

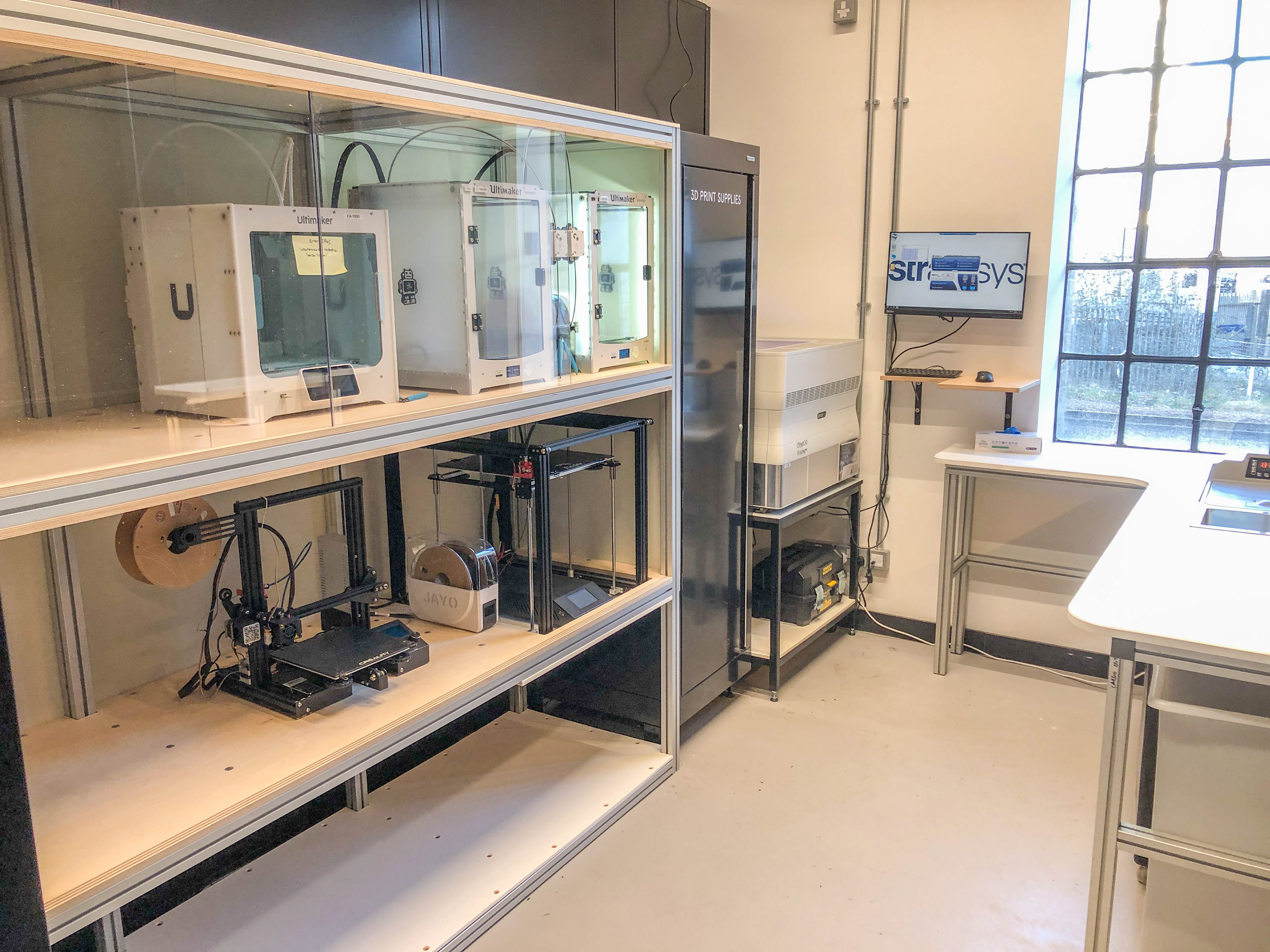

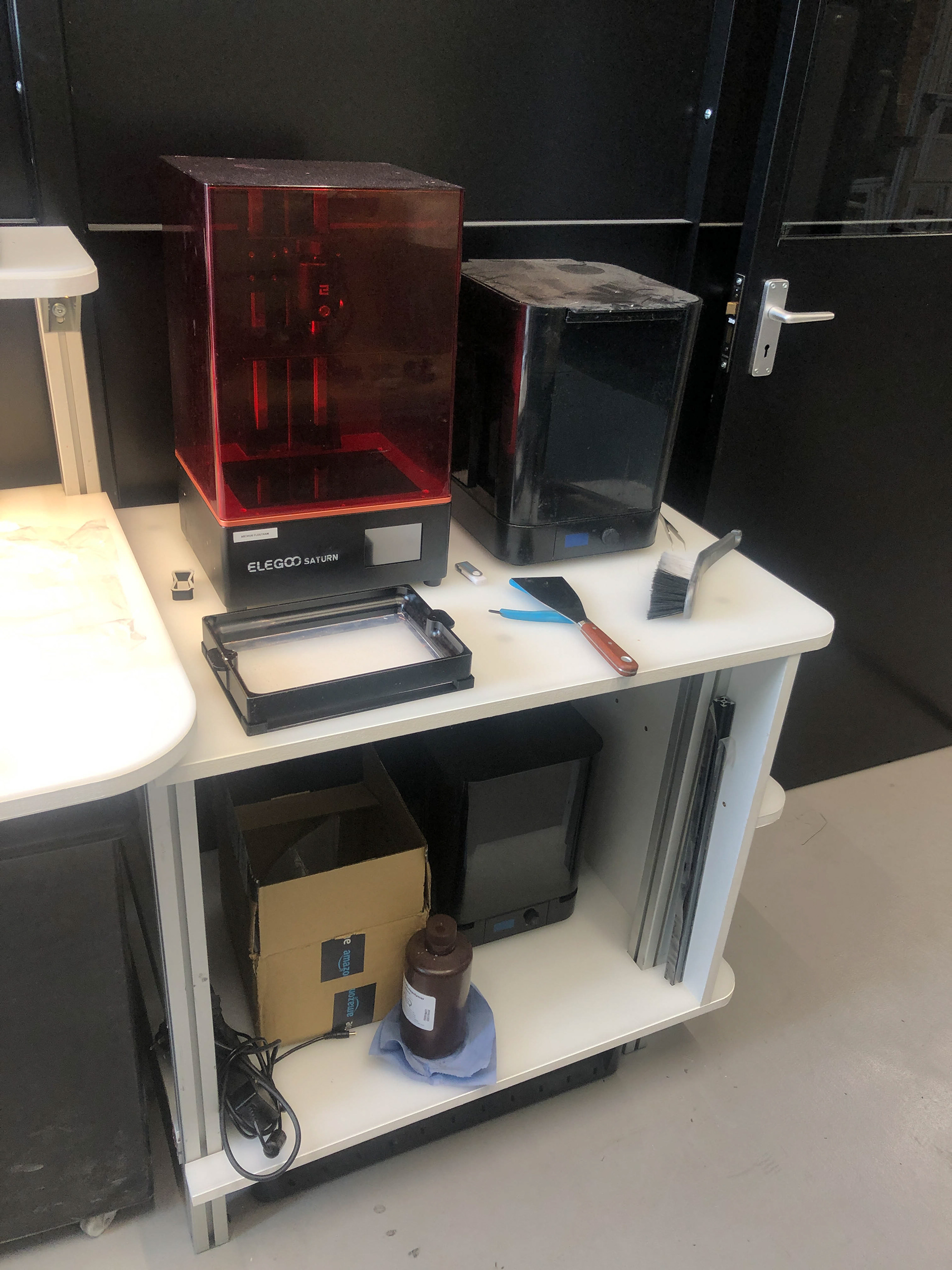

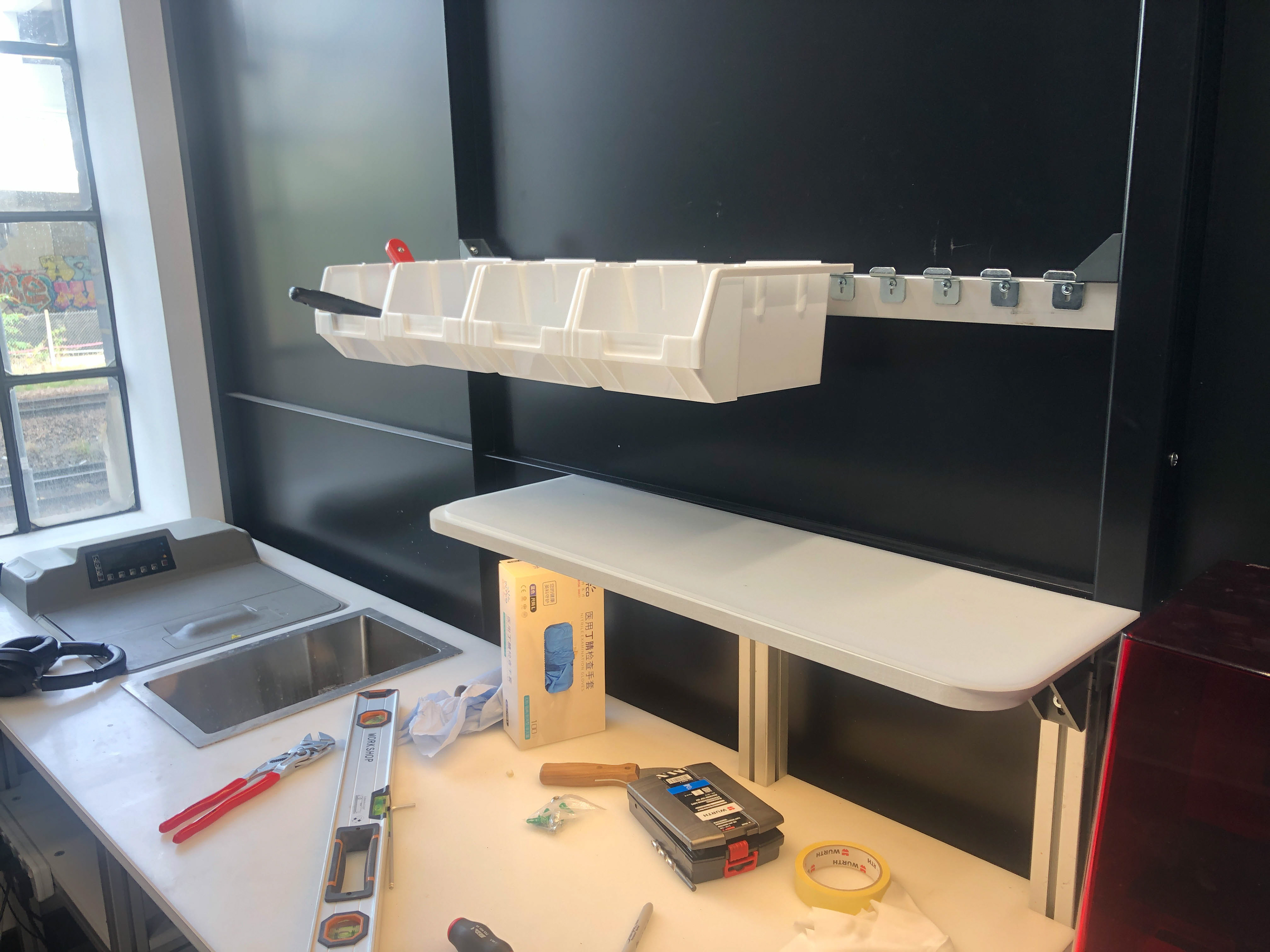

3D Print Room Upgrade

Fully responsible for the design and construction of the bespoke print room. Great attention to improve user interactions and workflow of each machine.

Introduced new digital (Atlassian JIRA) and physical workflows to significantly improve turnaround time for parts.

Layout keeps the space feeling open and light.

- HDPE surface topper to help keep the surfaces clean after using chemicals

- Wash tank built into bench for more ergonomic use

- Sink beside wash tank for rinsing parts without dripping chemicals over the floor.

- Custom keyboard shelf allowed for machine to fit in the room

- Sliding doors to maintain consistent temperature and humidity for improved print reliability

- Built in shelf lighting

- Temperature and Humidity Monitoring

- Wash tank built into bench for more ergonomic use

- Sink beside wash tank for rinsing parts without dripping chemicals over the floor.

- Custom keyboard shelf allowed for machine to fit in the room

- Sliding doors to maintain consistent temperature and humidity for improved print reliability

- Built in shelf lighting

- Temperature and Humidity Monitoring

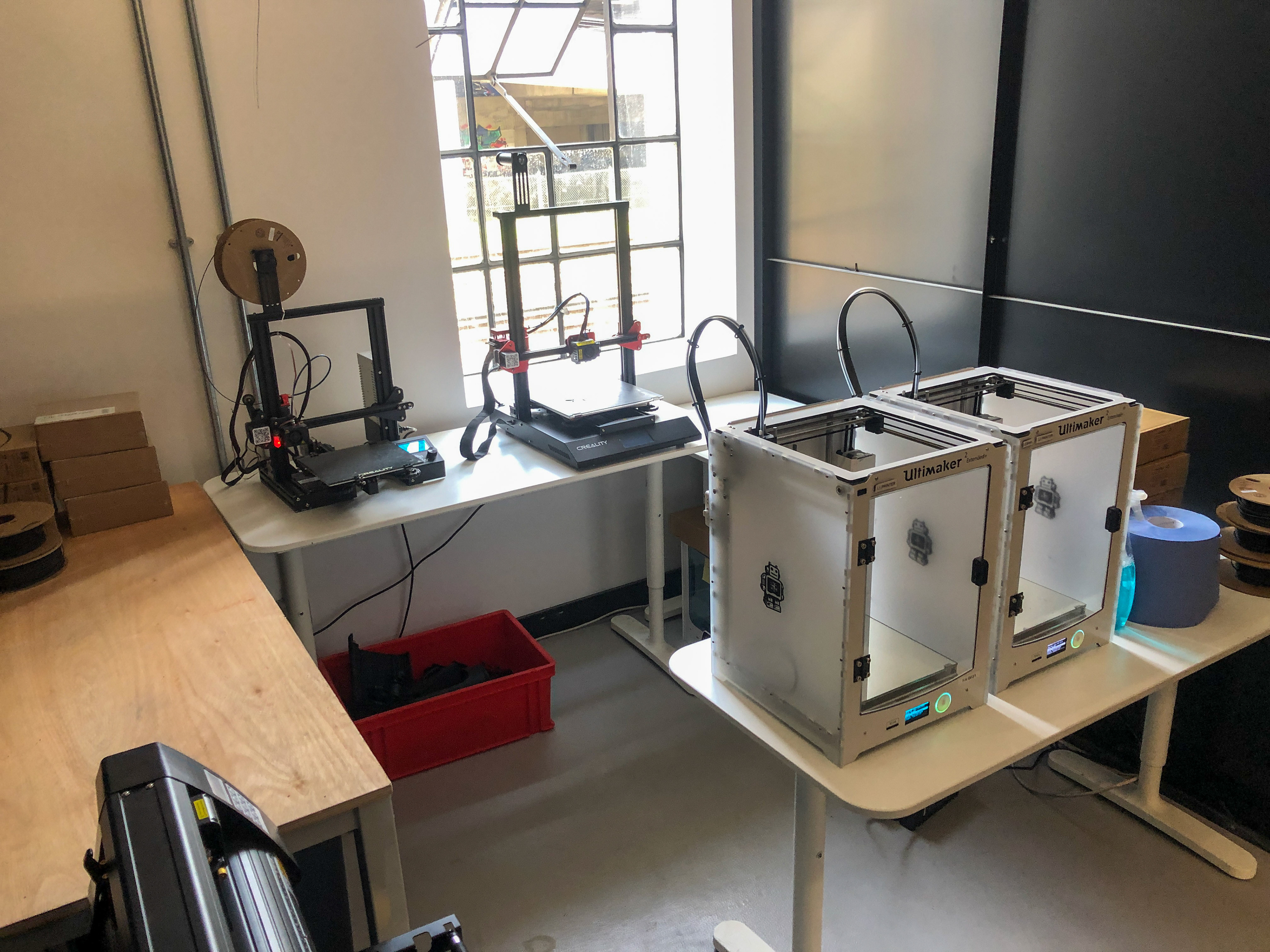

Before

Before

After

After

After

After

Later Addition

Later Addition

Plastics Area Upgrade

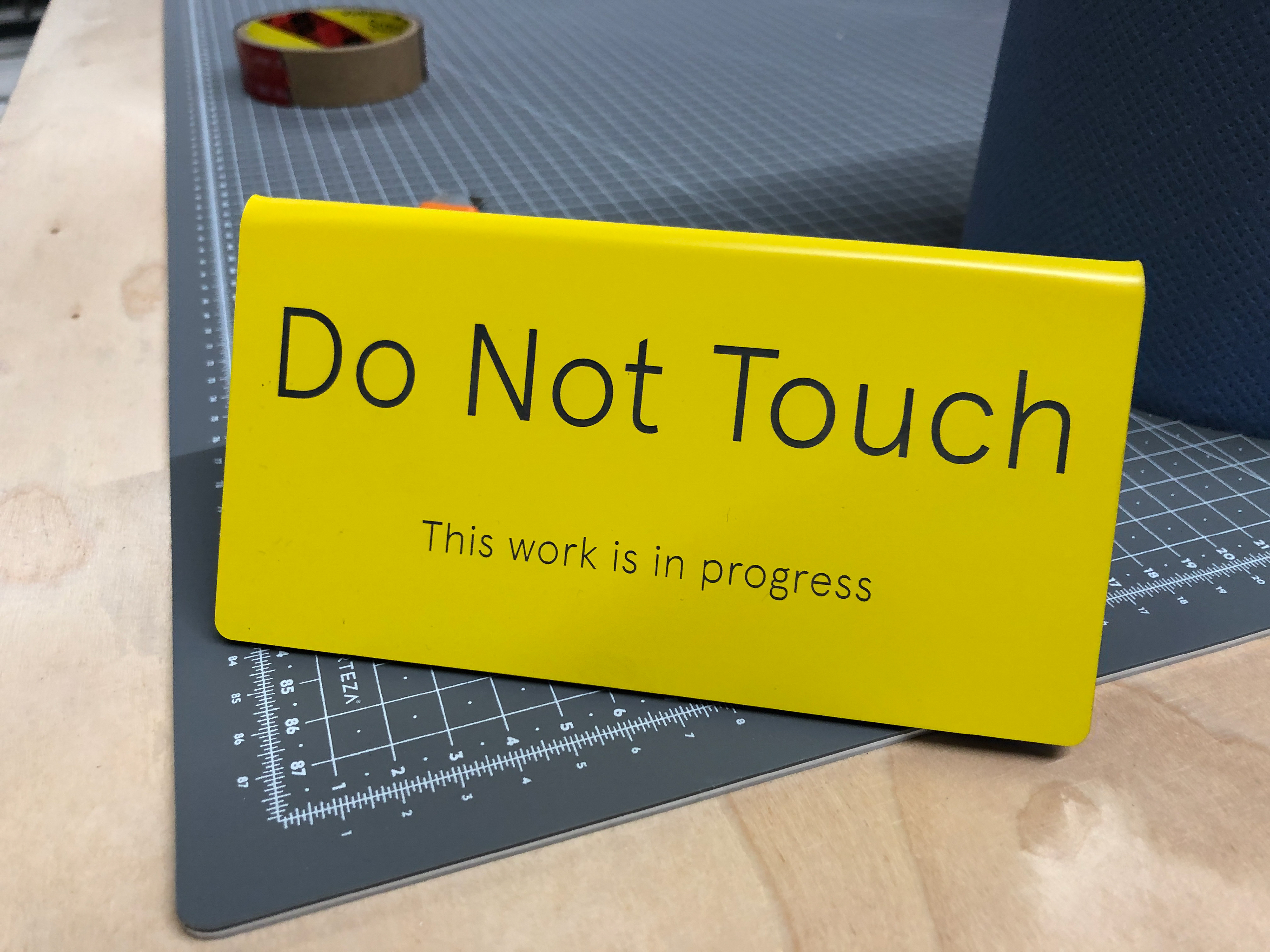

Custom Signage, Tool Cabinet Organisation, CNC Tool Management