Product Design and Electromechanics

I thoroughly enjoy the design process and use my technical knowledge to design efficient solutions to problems.

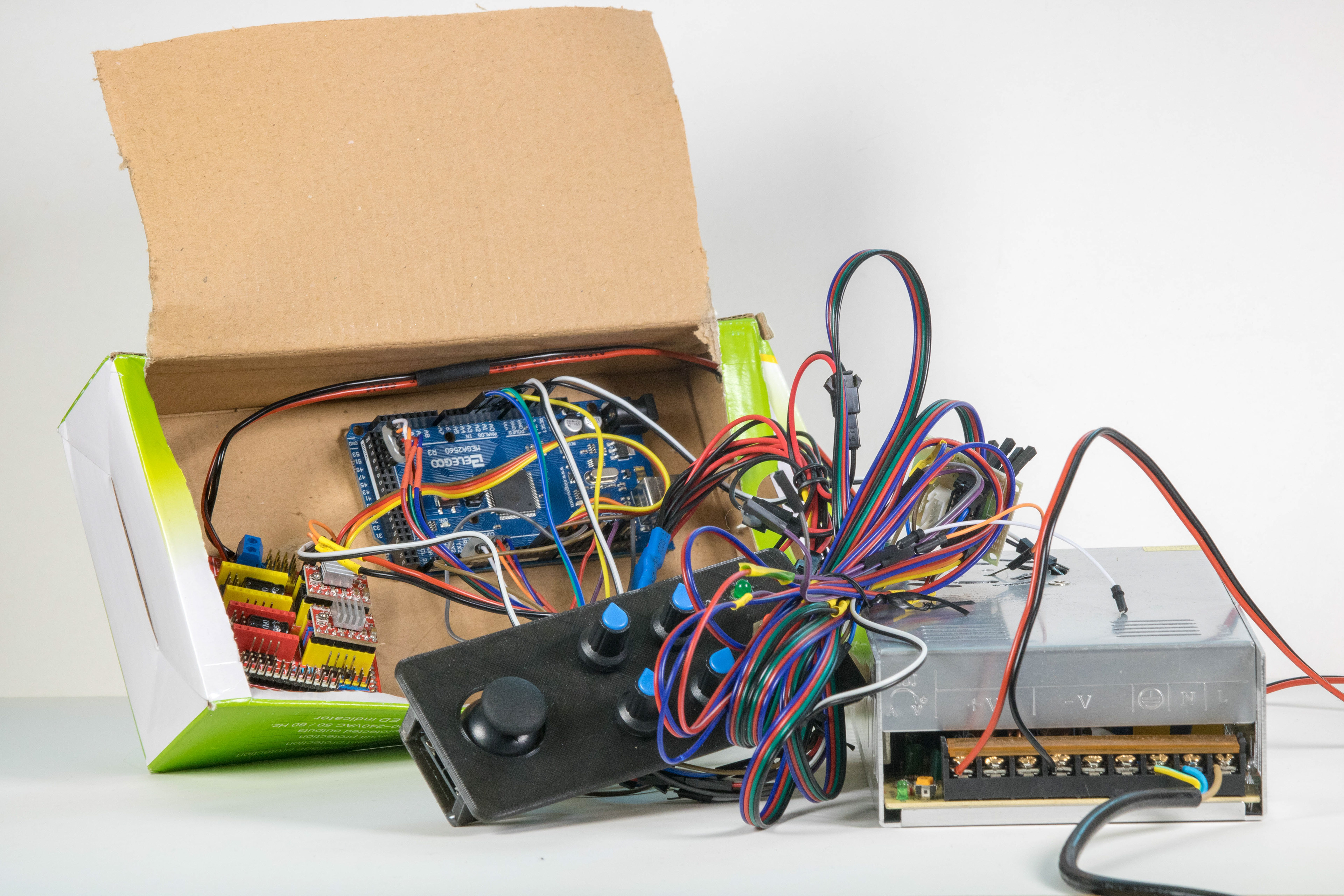

I have a strong enthusiasm for anything that makes use of movement, electronics and lighting. I have taught myself how to use electrical components like Arduino, LEDs and stepper motors. When the opportunity occurs I strive to use what I have learned to help benefit the outcome of the project.

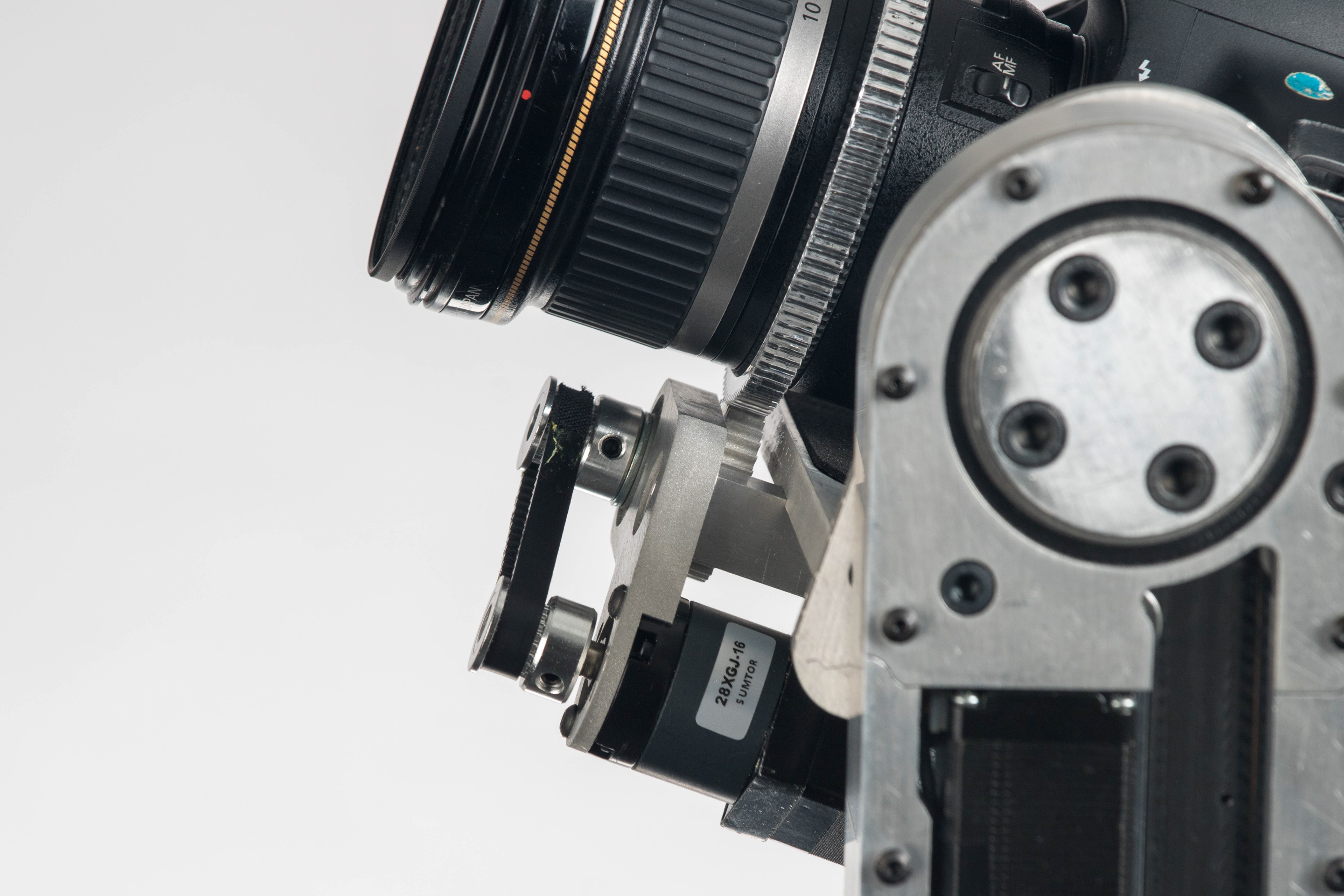

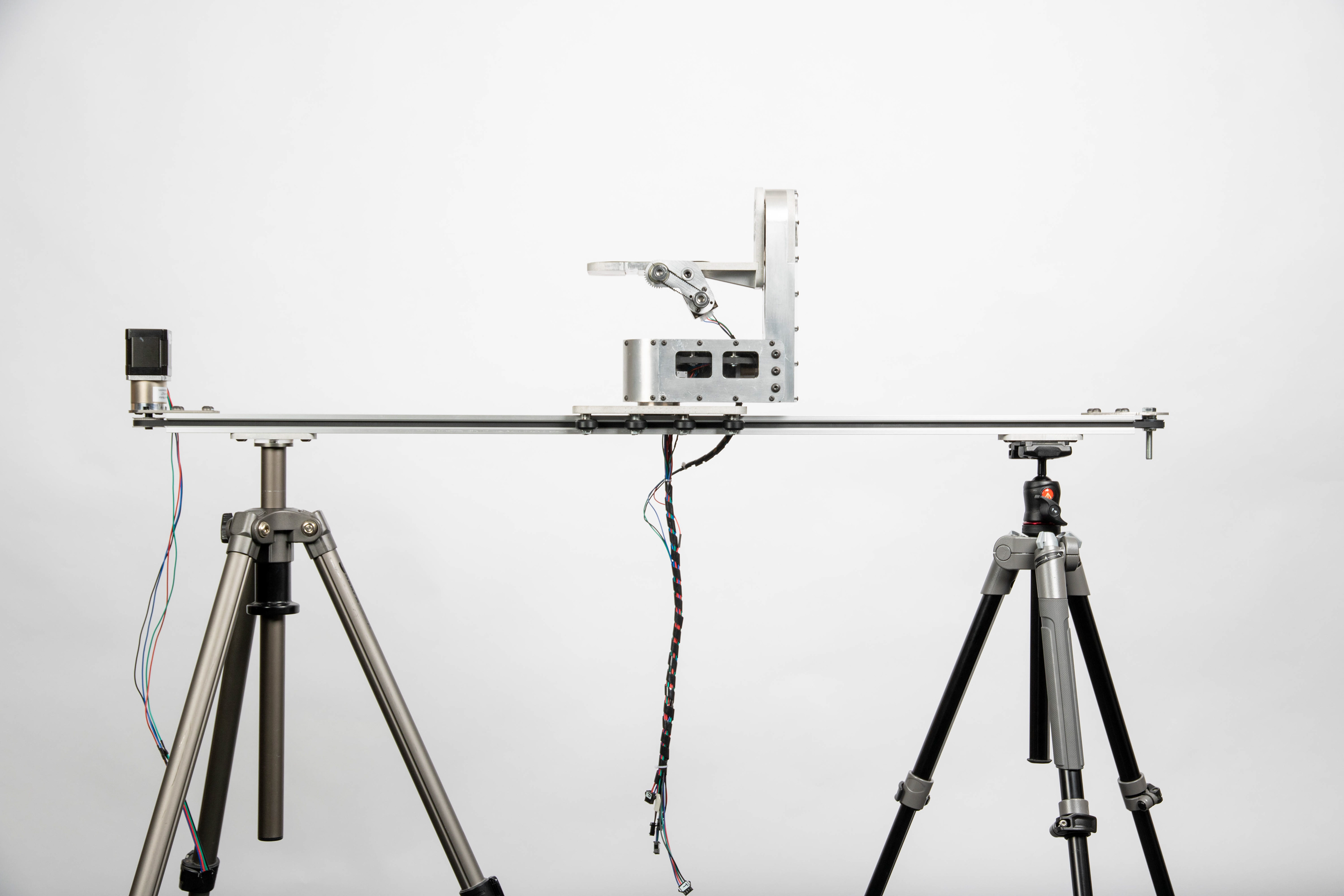

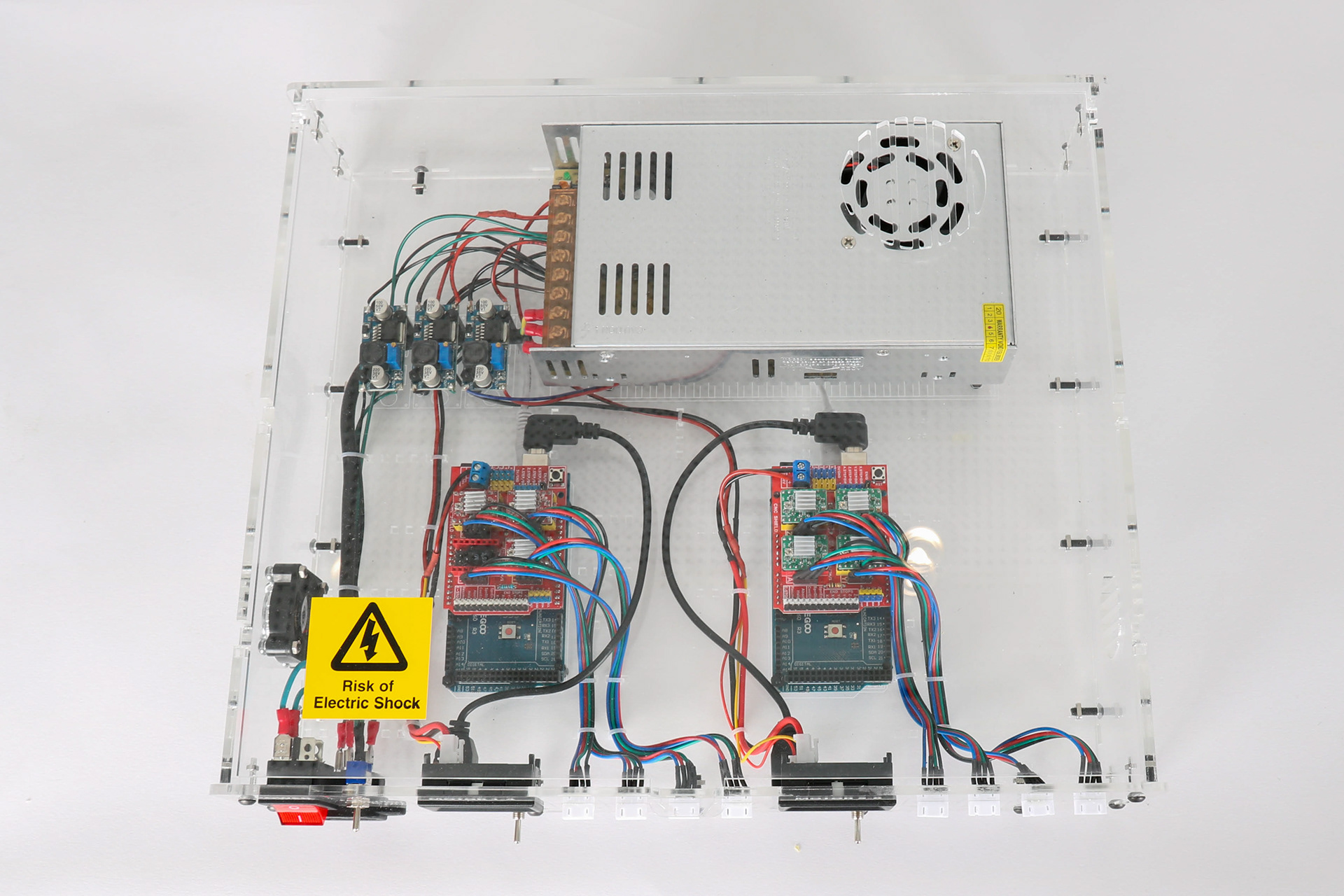

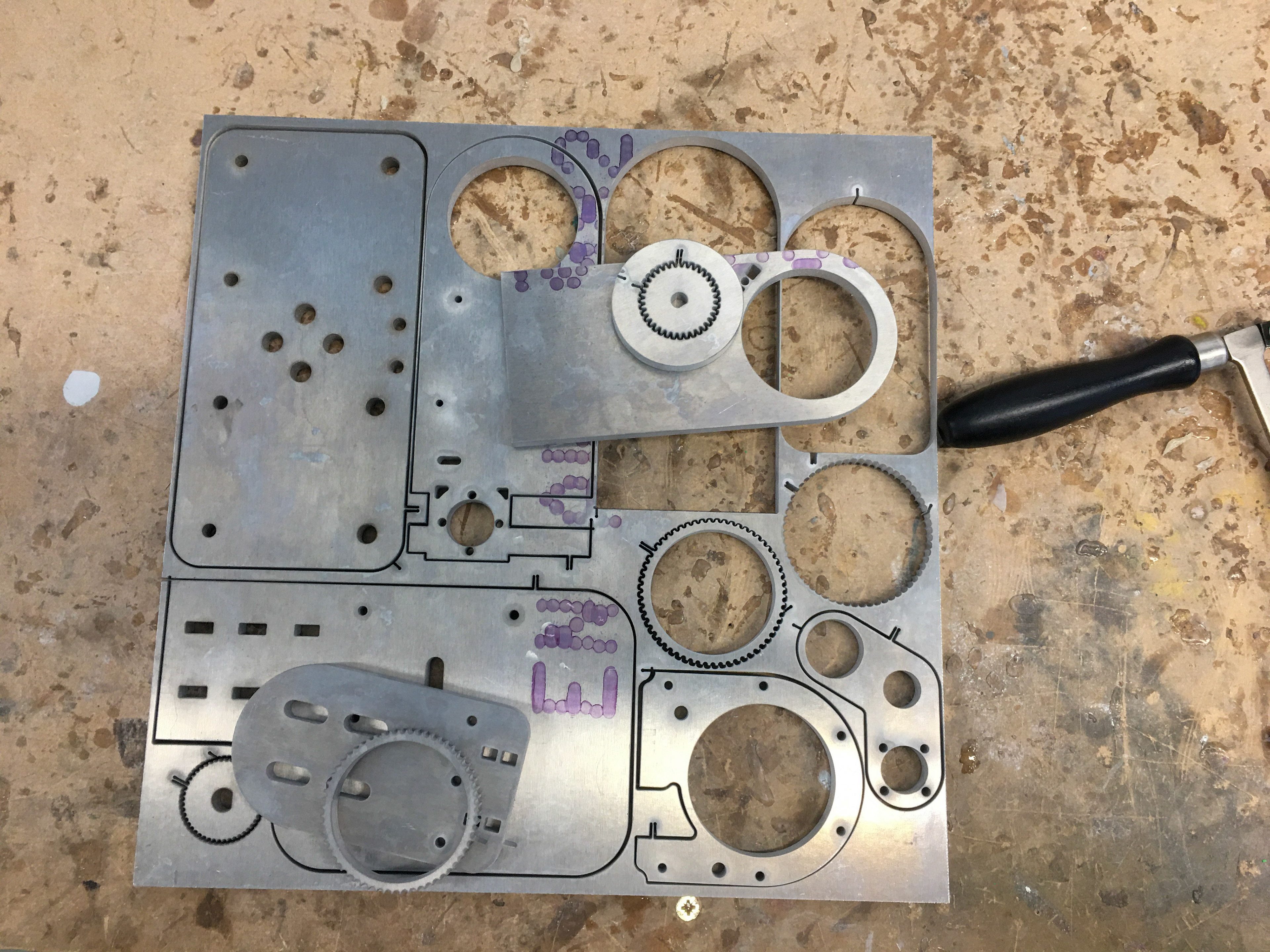

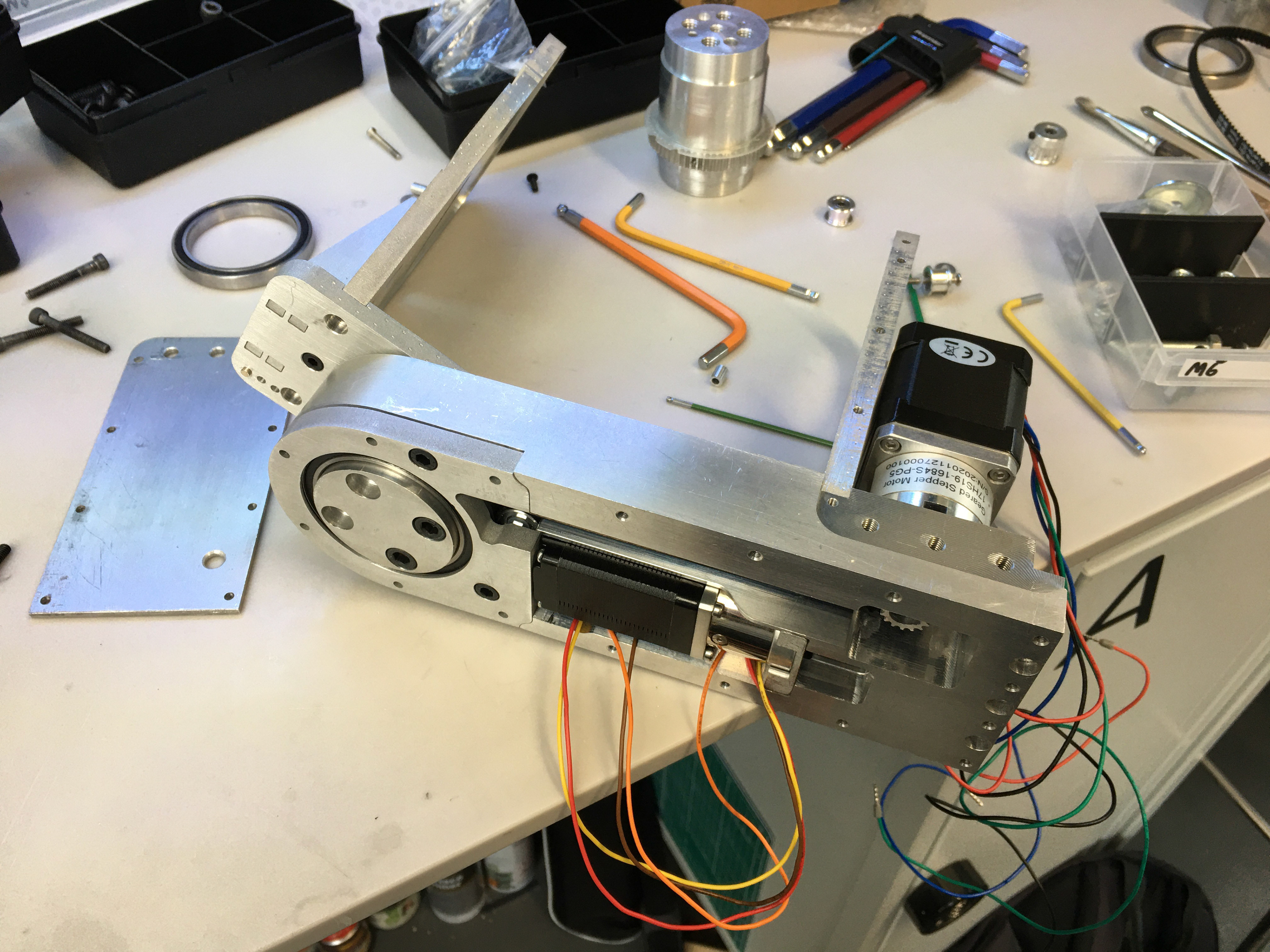

Motion Control Rig and Minature Model

My vision was to design, build and operate a motion control system to explore a classic film making technique of miniature filming by recreating a selection of CGI animations but with a real model against a green screen.

This project was inspired by the 2020 TV show The Mandalorian where the SFX team created a custom motion control rig to film a model miniature of a ship. This was done to mitigate the challenges of rendering reflective surfaces in CGI and to pay homage to the original Star Wars miniatures.

I was awarded the Dean’s Prize for excellent problem-solving and technical achievement for this project.

This 14-week project combined all skills and qualities that I mastered during my degree, including:

- Exceptional time planning

- Thorough use and understanding of a range of making techniques

- Creative and Innovative Problem-solving

- Thorough use and understanding of a range of making techniques

- Creative and Innovative Problem-solving

Features

- Repeatable movement

- Pan and tilit control

- Focus or zoom Control

- Travel control

- >360 degree rotation of any axis

- Control box capable of upto 8 axis simultaneously

- Lighting trigger/dimmer box communication to software via DMX

- Repeatable movement

- Pan and tilit control

- Focus or zoom Control

- Travel control

- >360 degree rotation of any axis

- Control box capable of upto 8 axis simultaneously

- Lighting trigger/dimmer box communication to software via DMX

Reverse engineered similar products (moving stage spotlights) to investigate the electrical and mechanical mechanisms to inform my design

I needed to make sure the stepper motors I chose would have enough torque to move the rig. I tested motors by slowly increasing the load until they would slip. I tested both static toque and running toque

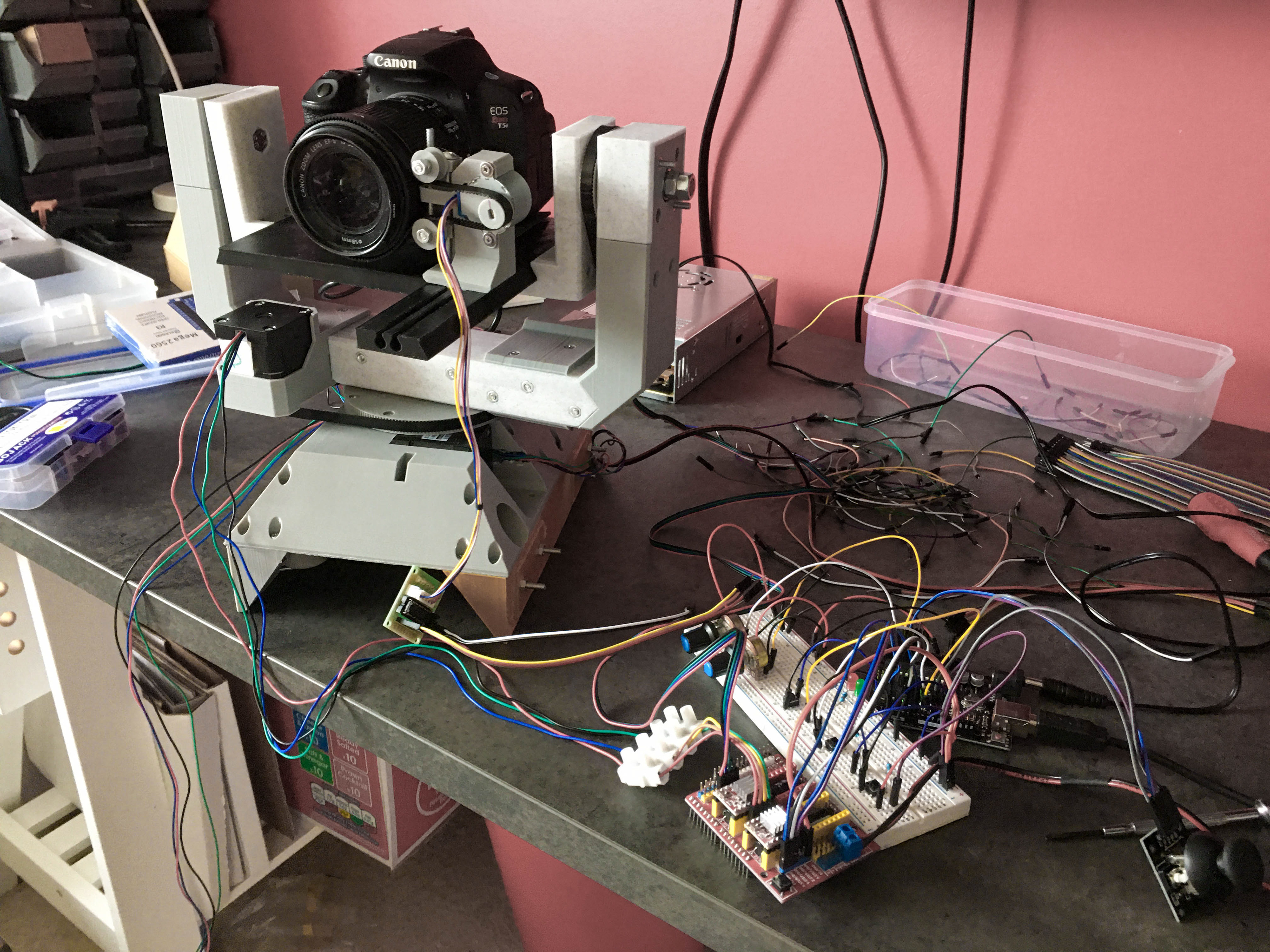

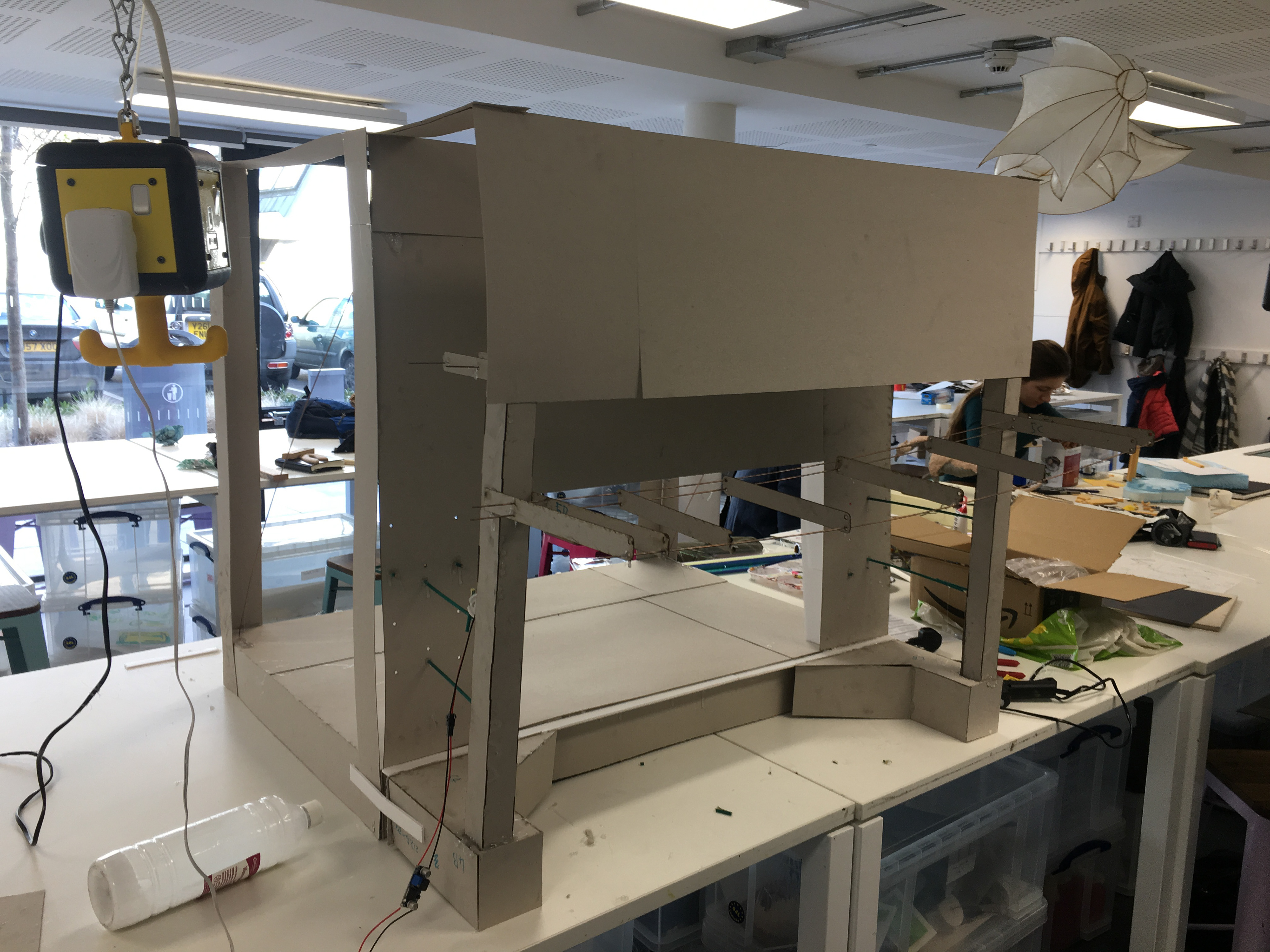

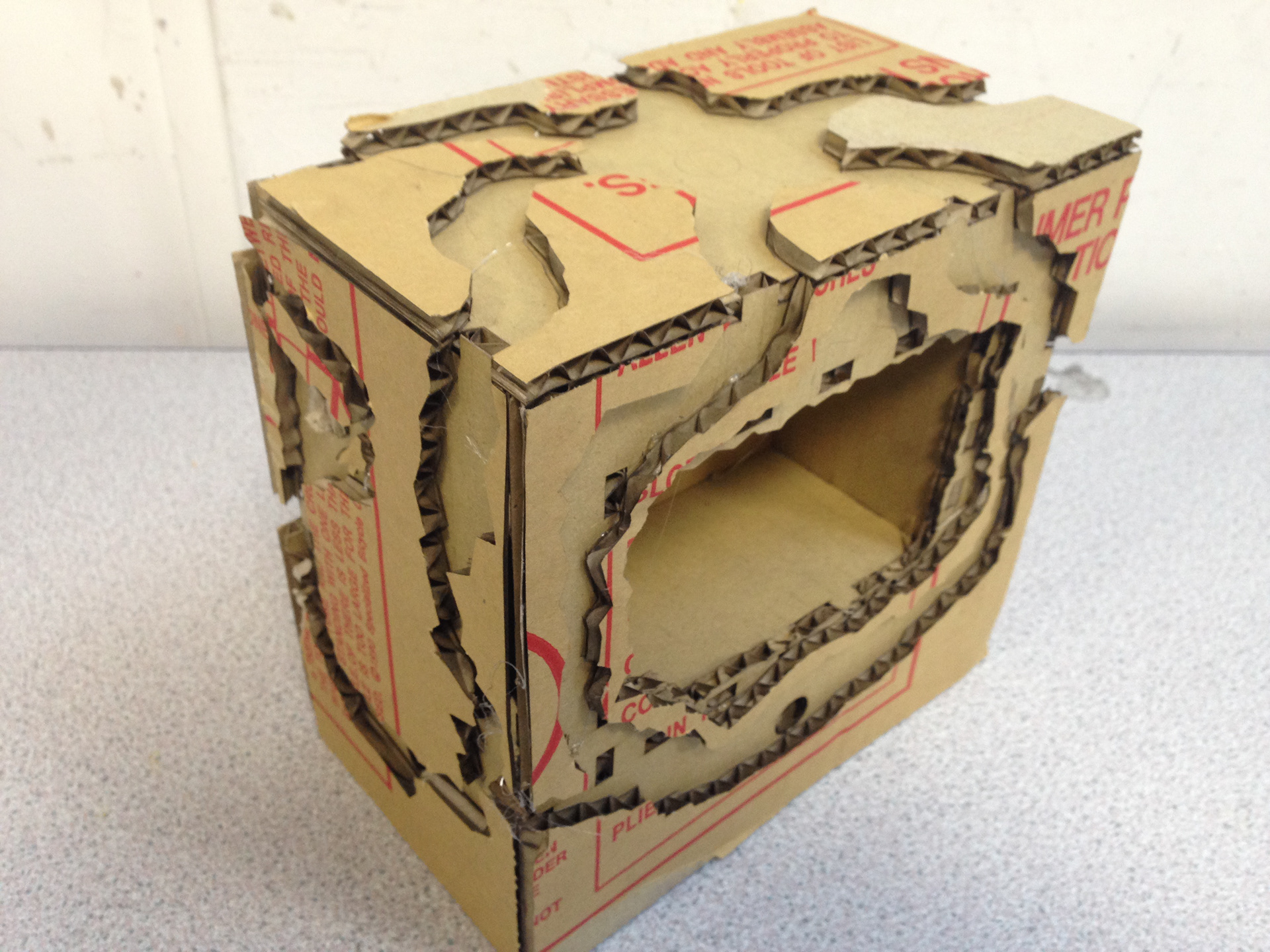

Before committing to build my final aluminium version I made a prototype from cheaper materials to test my design

Before committing to build my final aluminium version I made a prototype from cheaper materials to test my design

The Rocket was mostly acrylic, model board and SLA printed parts. I included multiple addressable fibre optic lights. I planned shots in MAYA, designed and made the rig and used Dragon Frame stop-motion animation to send signals to an Arduino which controlled the motors.

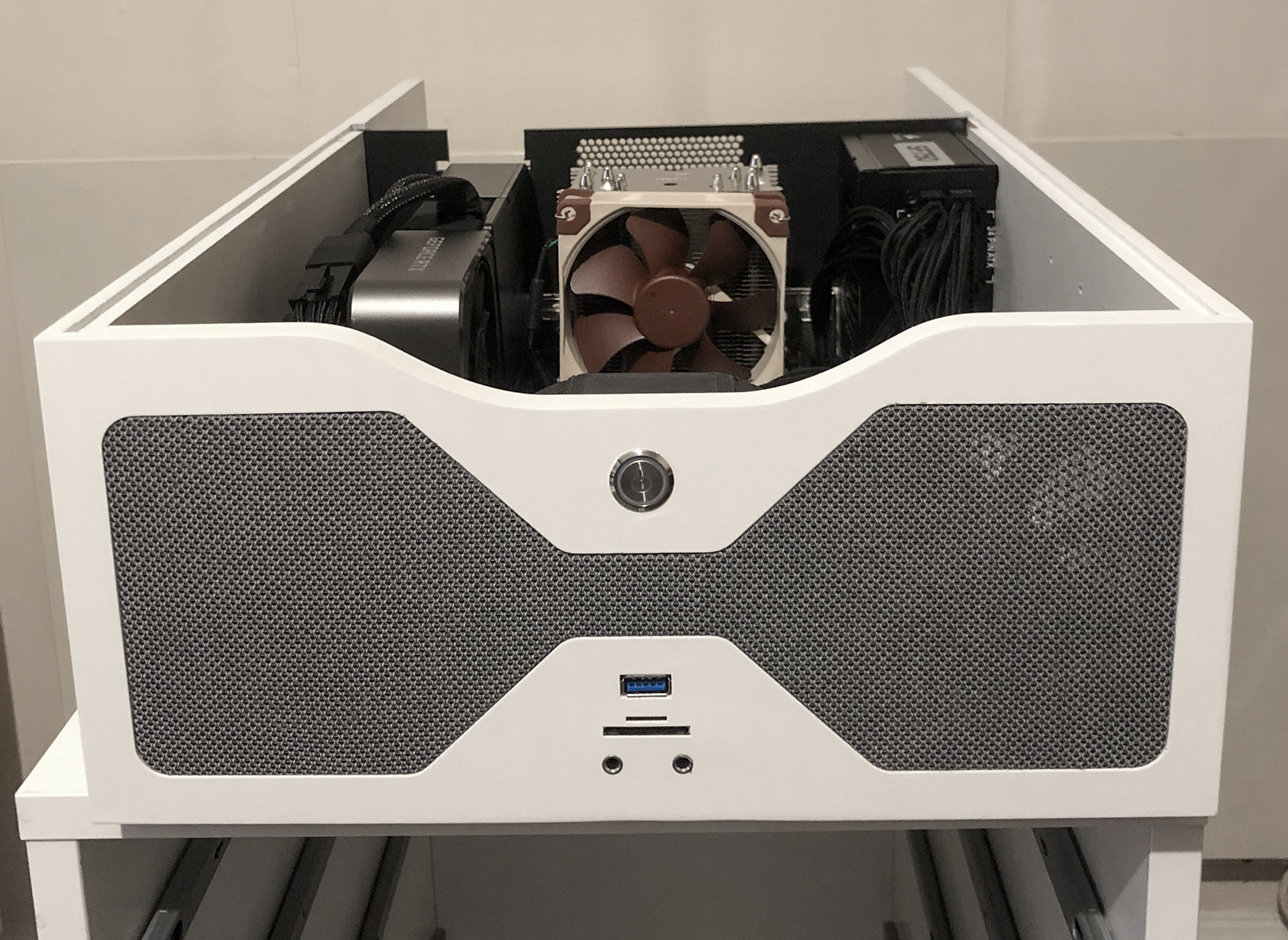

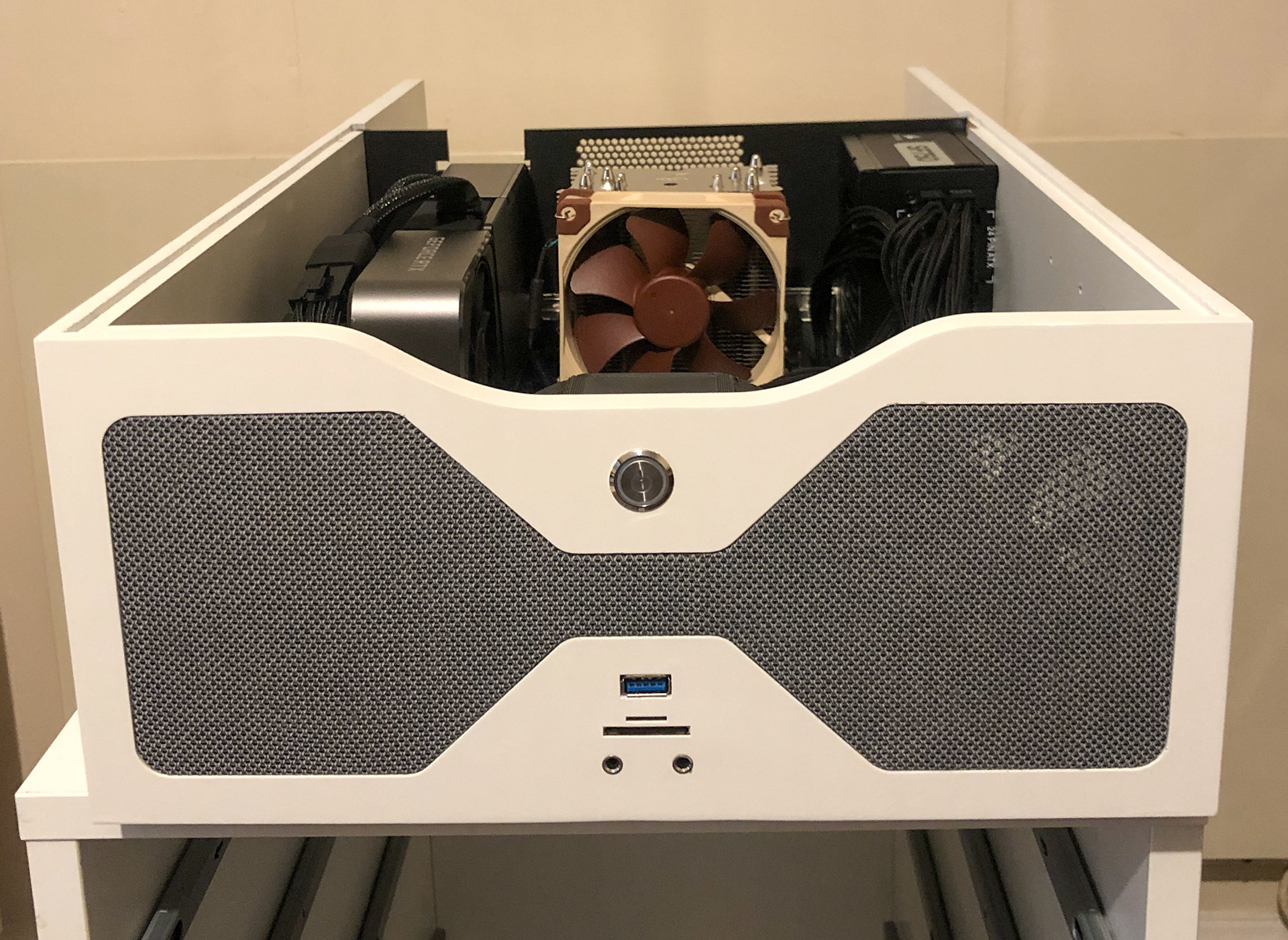

Custom Drawer PC

As a recent side project, I designed and built a custom computer case for my home office workstation. My old case took up too much space next to my monitor or got in the way of my legs when it was on the floor. Tackling this problem, I build a new computer, from scratch, directly into the set of drawers underneath my desk. This integral solution uses a server-style cooling system, drawing air in through the front and expelling it out the back. The result is a simple, aesthetic and functional work environment.

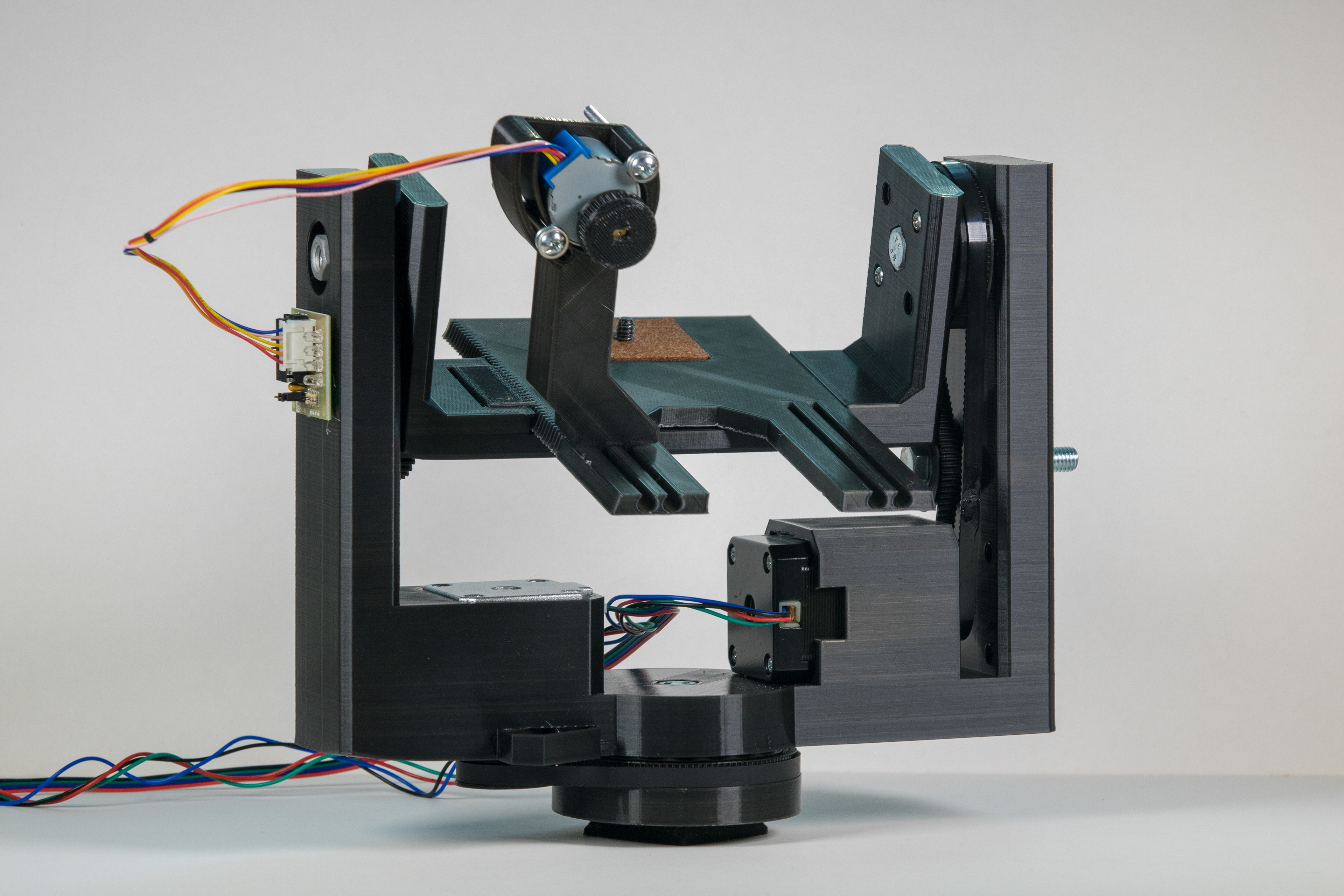

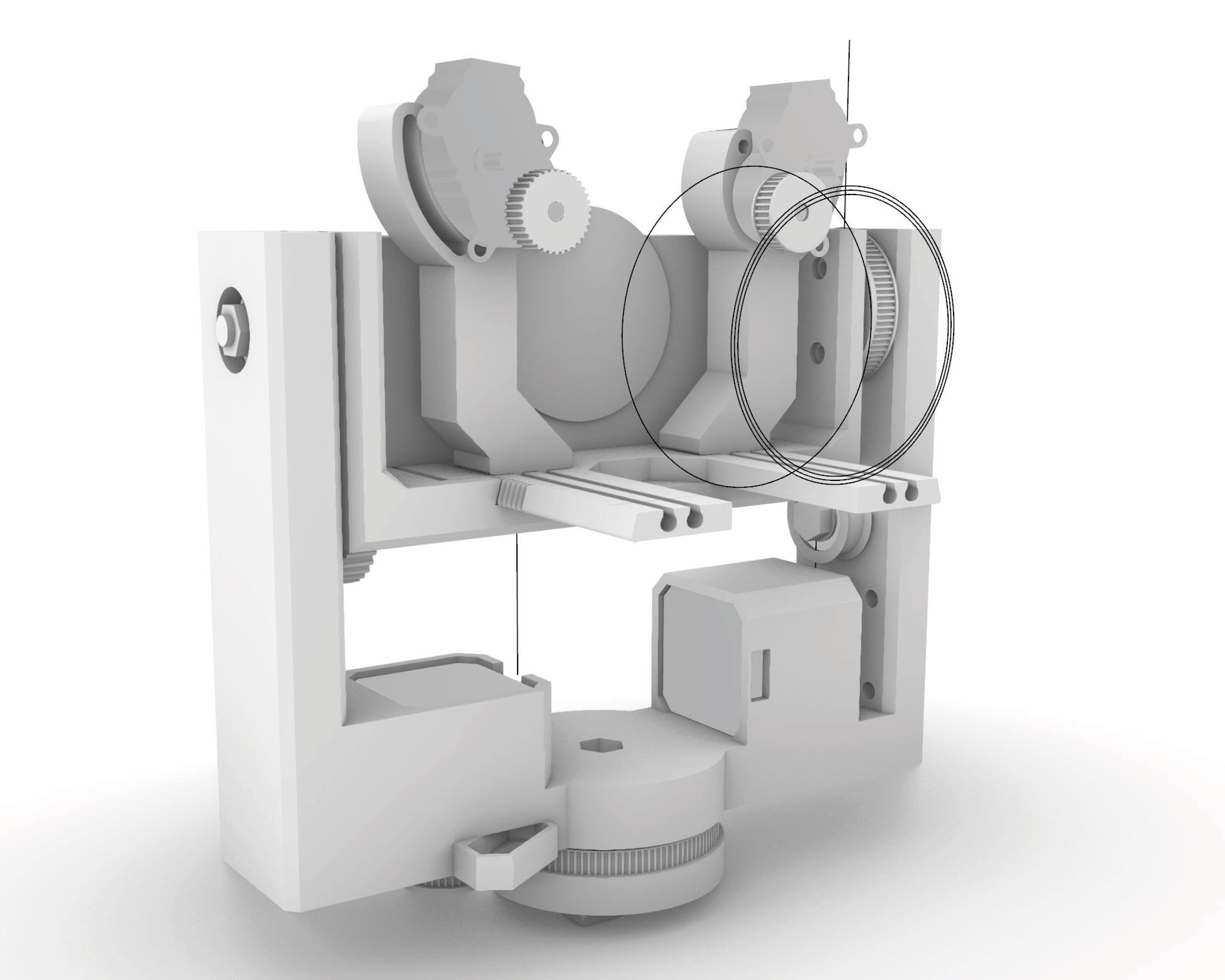

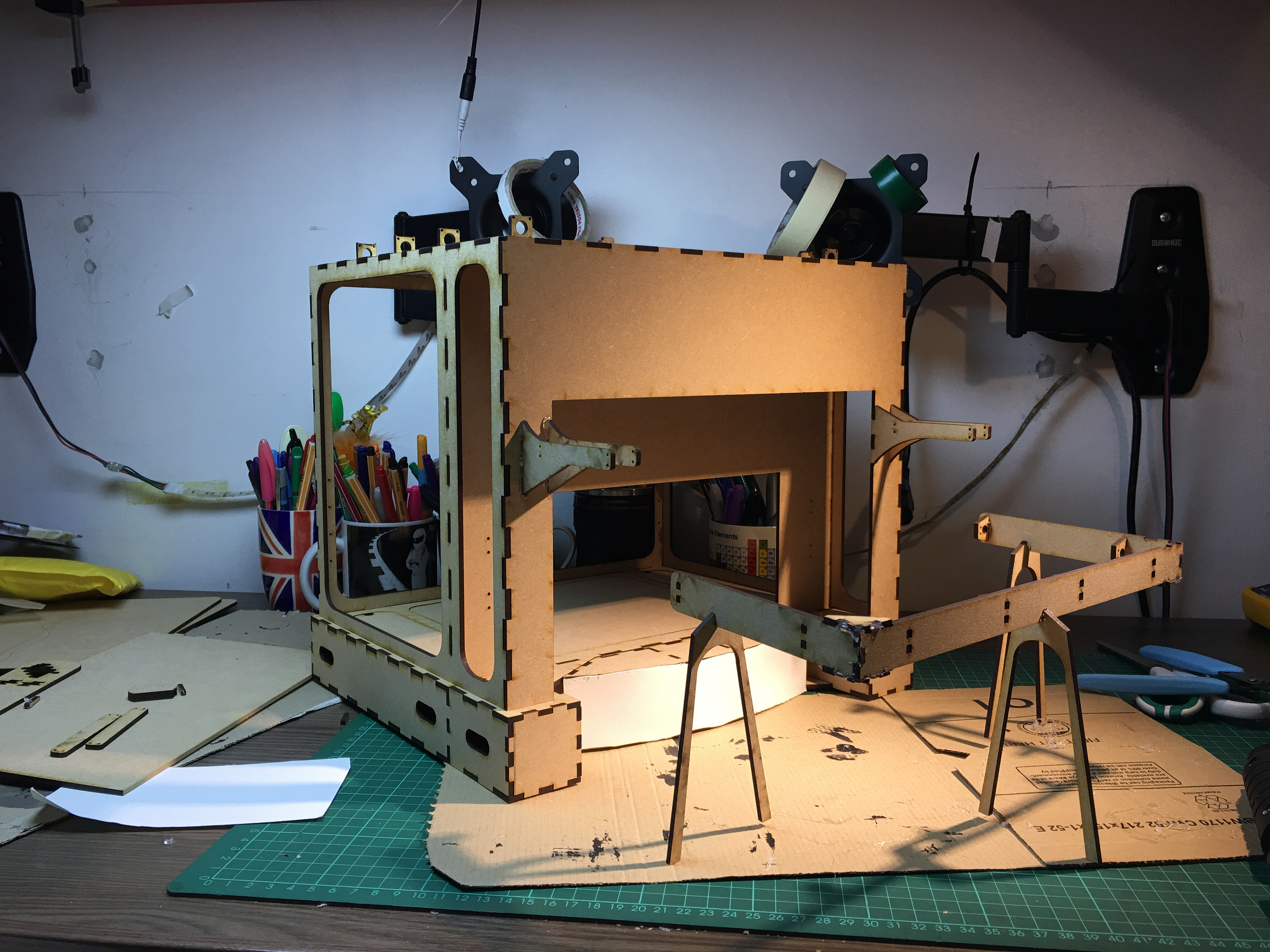

Low Cost DSLR Motion Control Rig

In 2020 I was the technical coordinator of the performing arts society at my university. Though lockdown it was were not host audiences at performances.

My idea was to set up recording/ live streaming of shows.

I designed and built this low cost motion control rig prototype with the aim to position several in the performance space for live broadcasting to remote audiences online.

Aims

- Use low cost components

- Be manufacturable from a standard 3D printer bed size of 220x220mm

- Small batch produced

- Have a smooth and stable movement to be used for live video

- Use low cost components

- Be manufacturable from a standard 3D printer bed size of 220x220mm

- Small batch produced

- Have a smooth and stable movement to be used for live video

Build

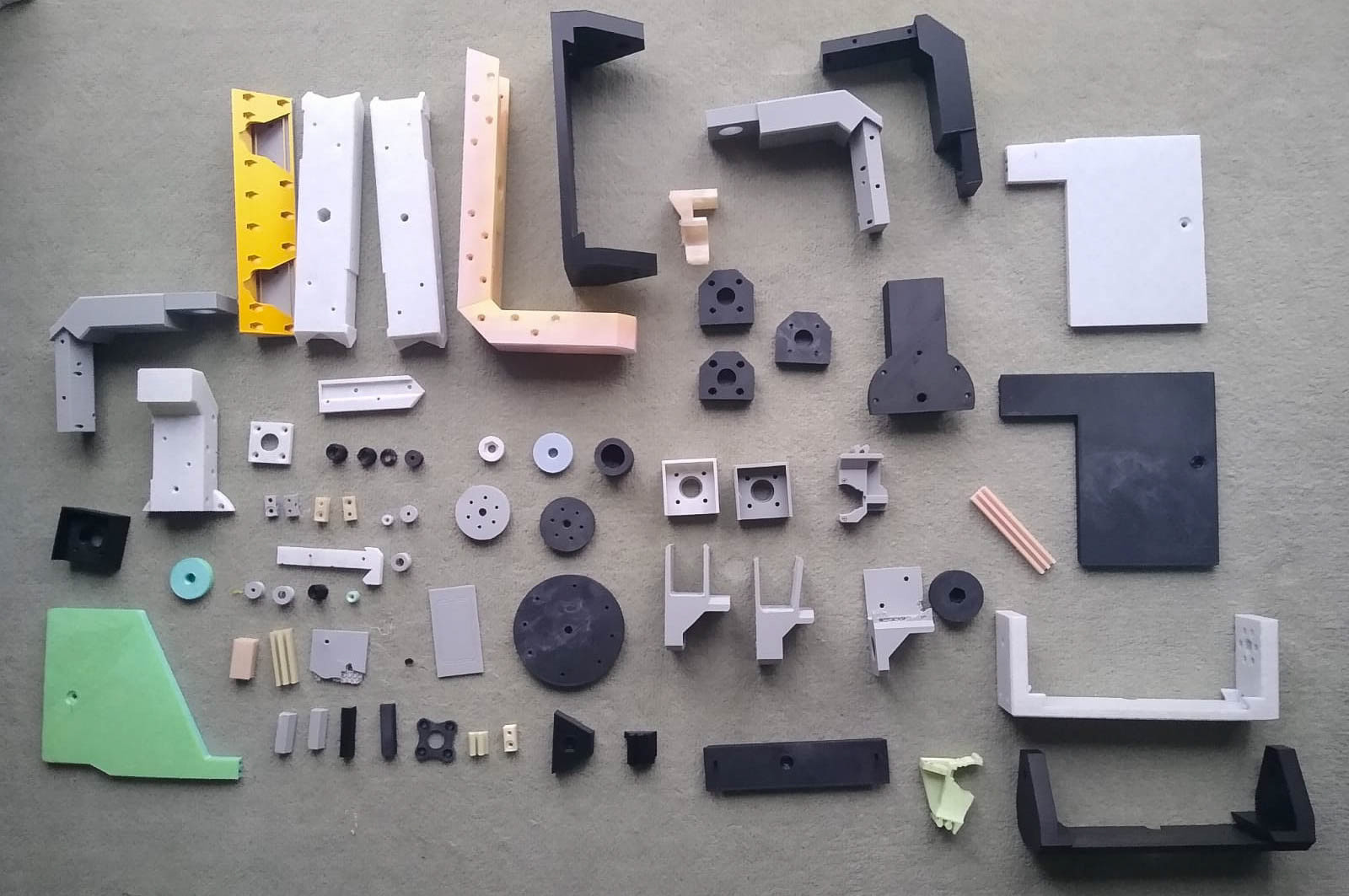

- I used FDM 3D printing for the majority of the components

- Movement was controlled with an Arduino and stepper motors

- Travel movement using an inexpensive 3x2 length of timber

- I used FDM 3D printing for the majority of the components

- Movement was controlled with an Arduino and stepper motors

- Travel movement using an inexpensive 3x2 length of timber

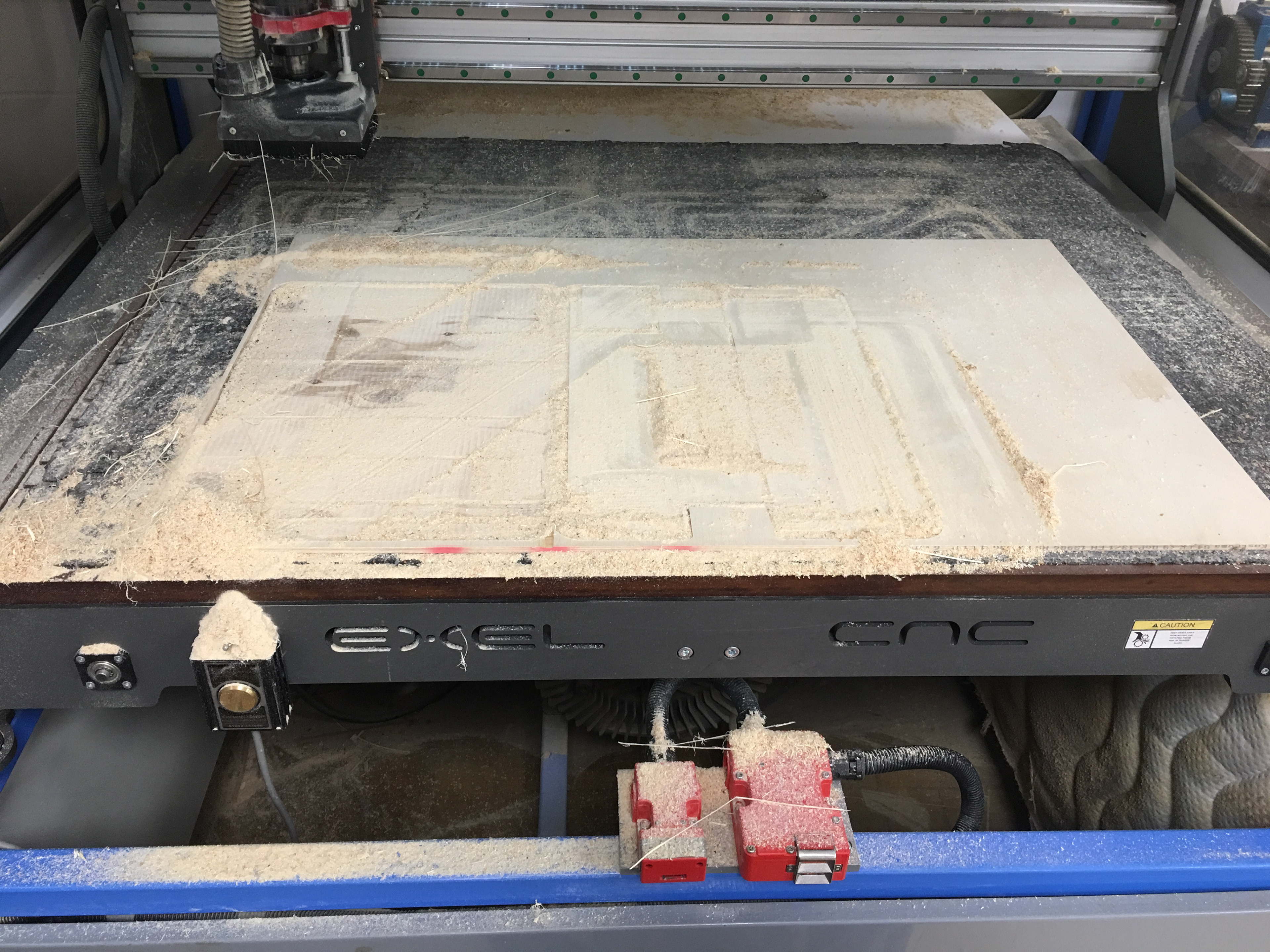

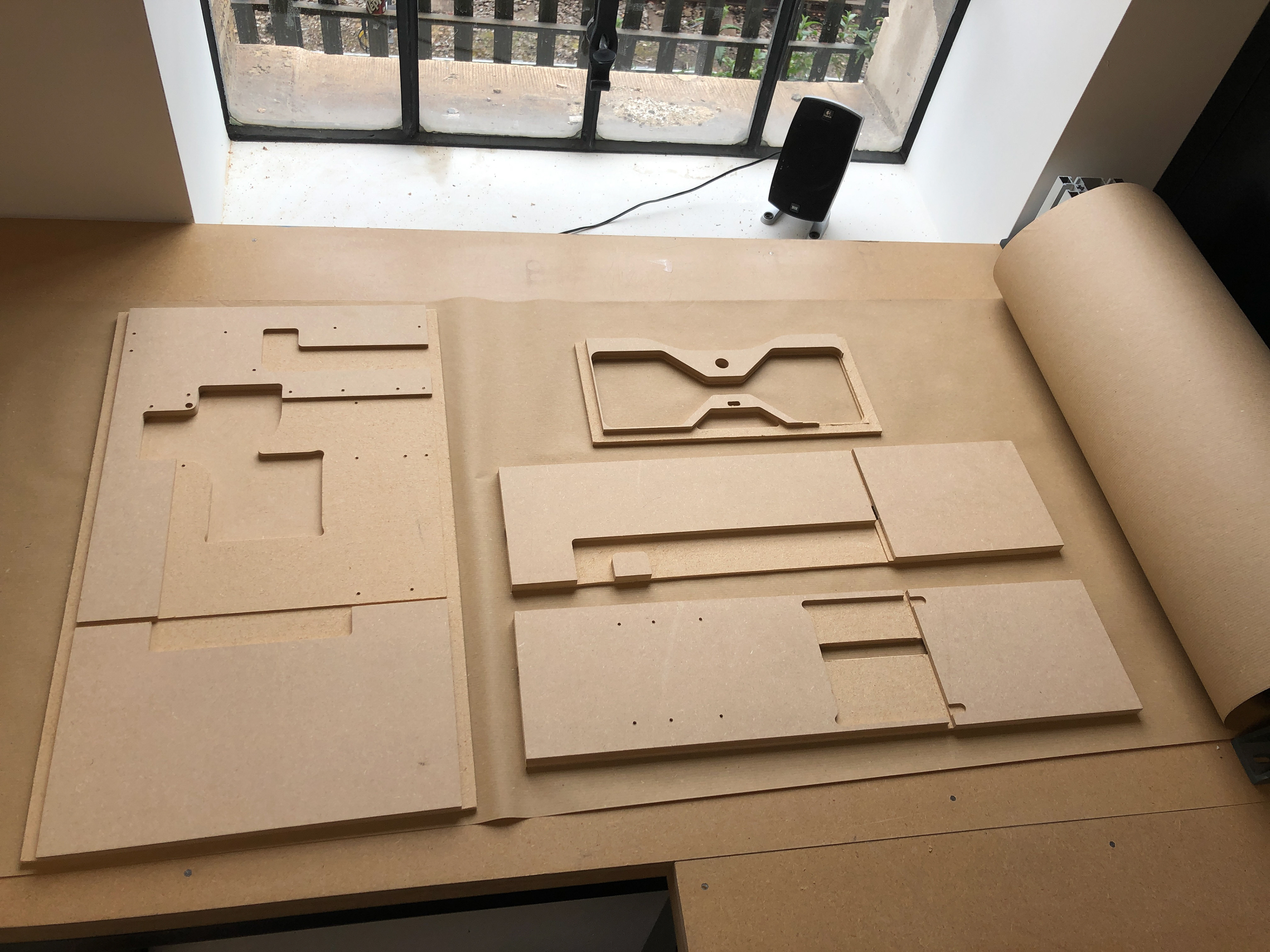

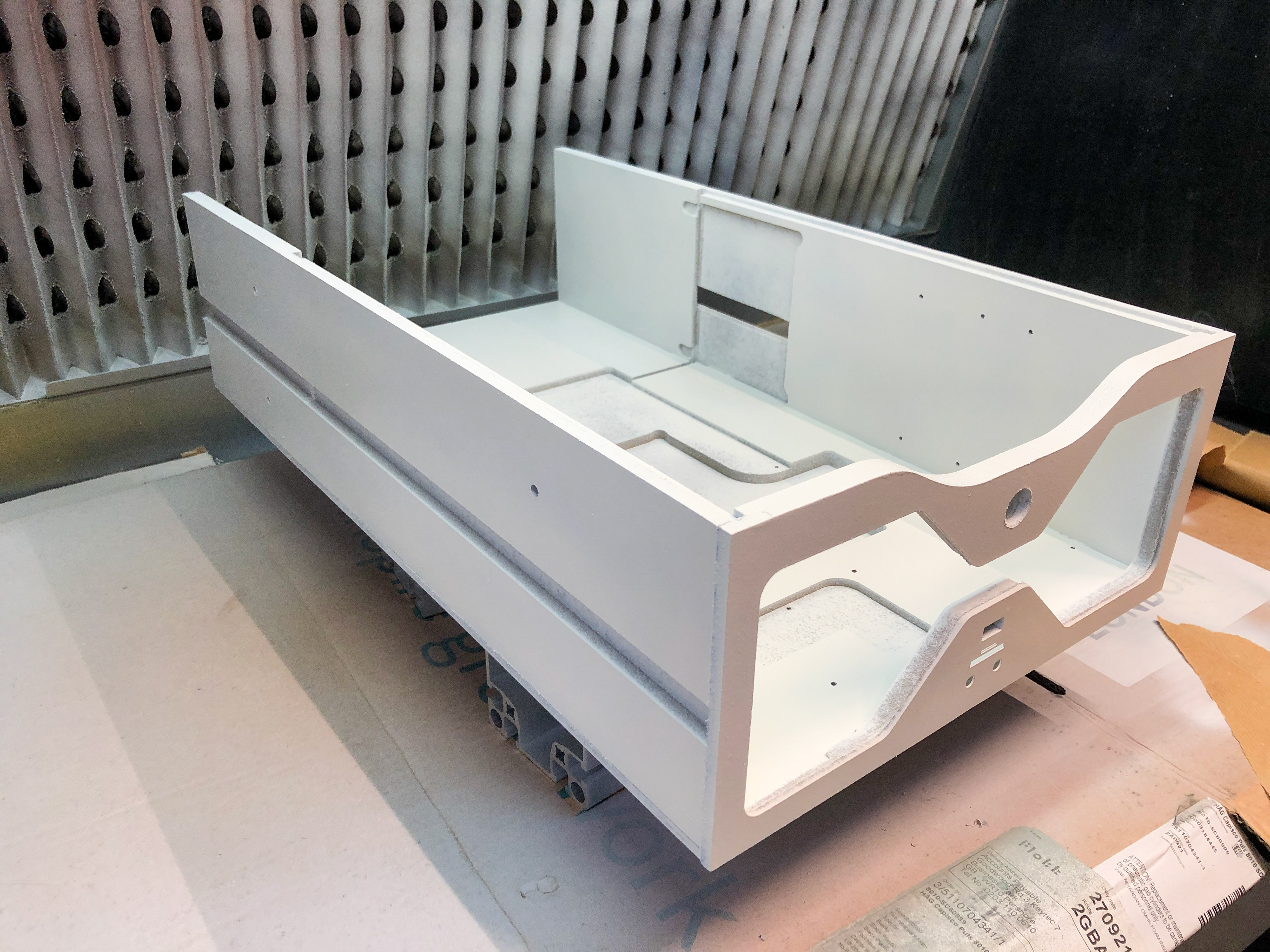

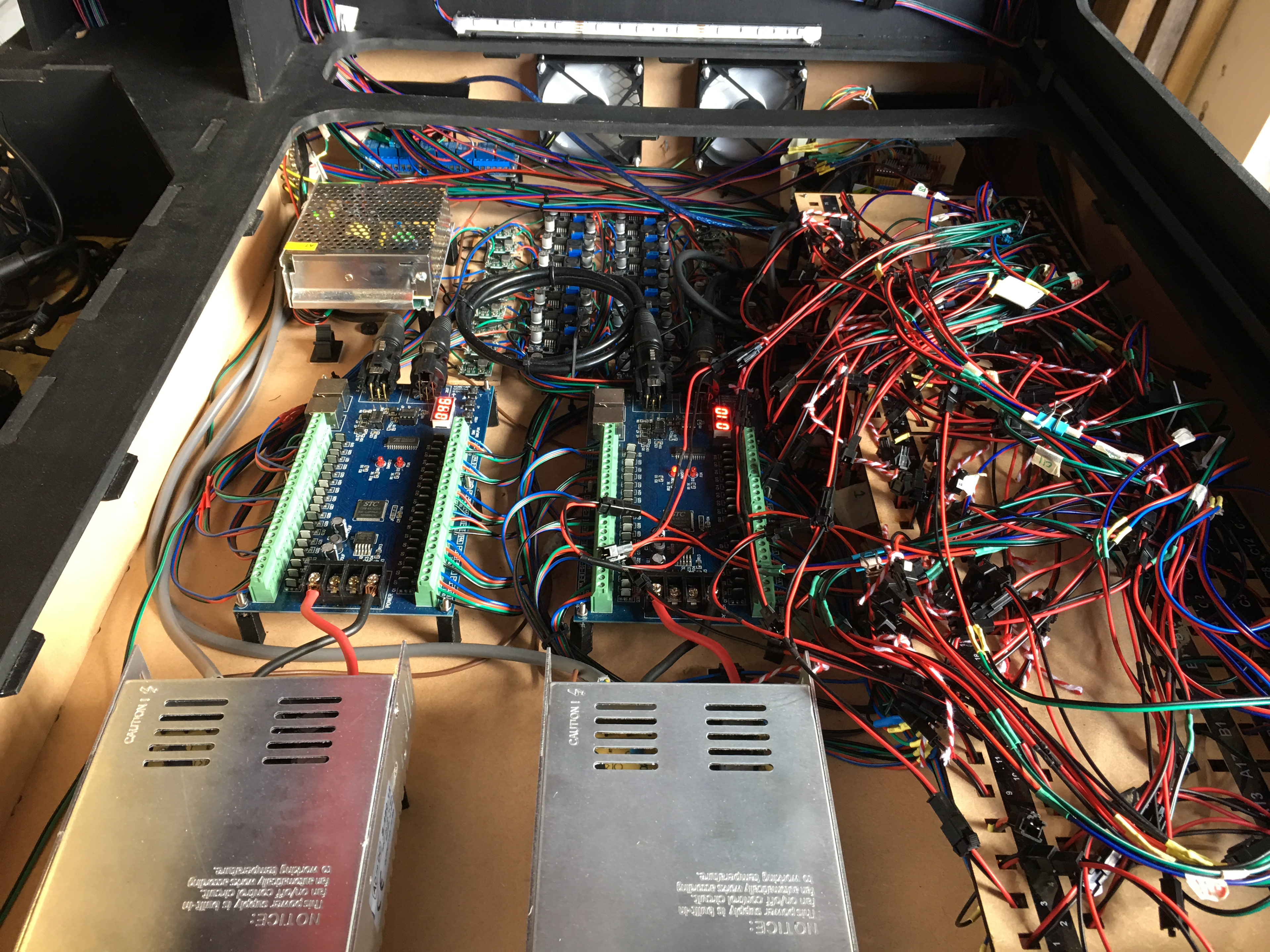

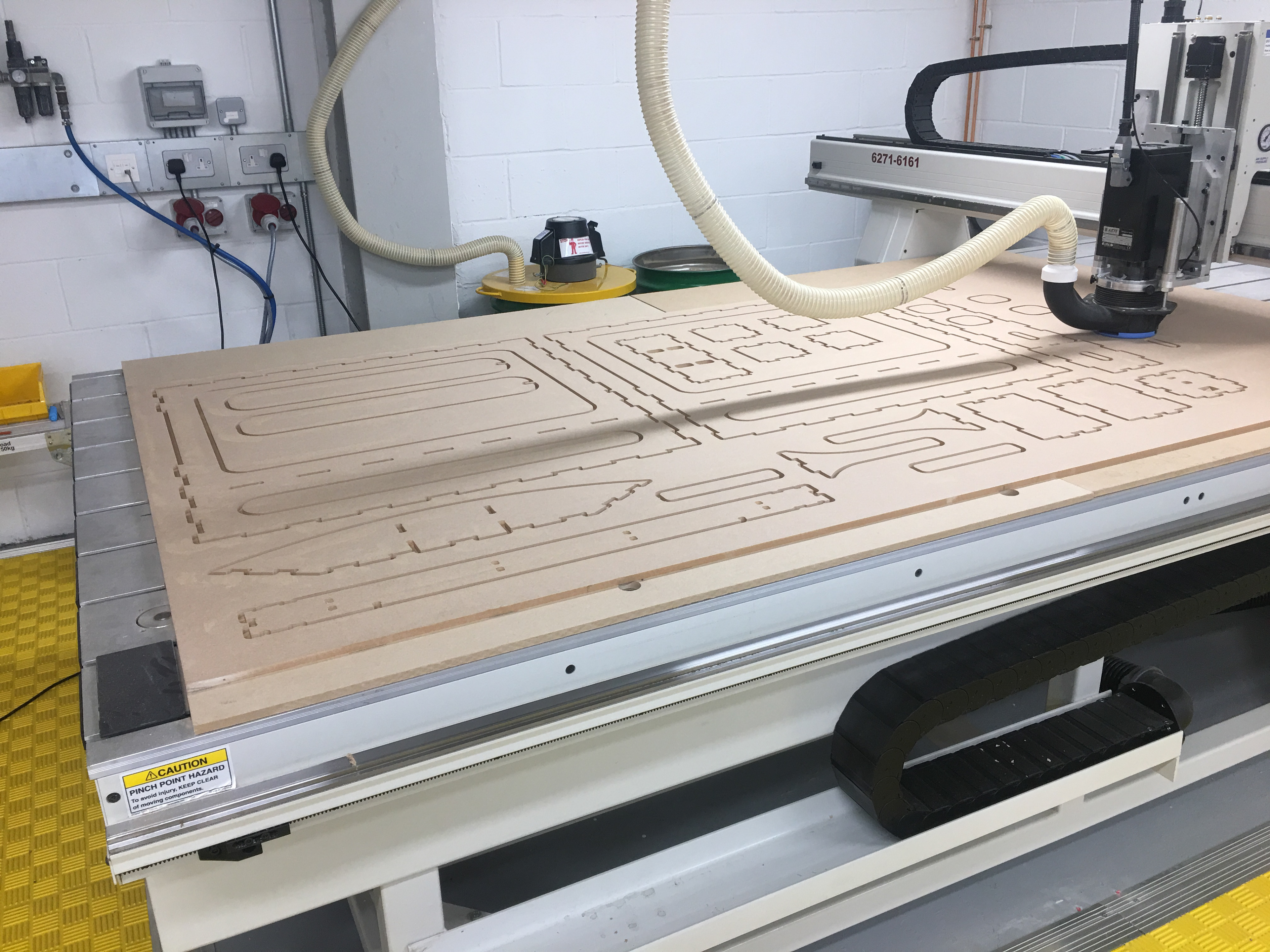

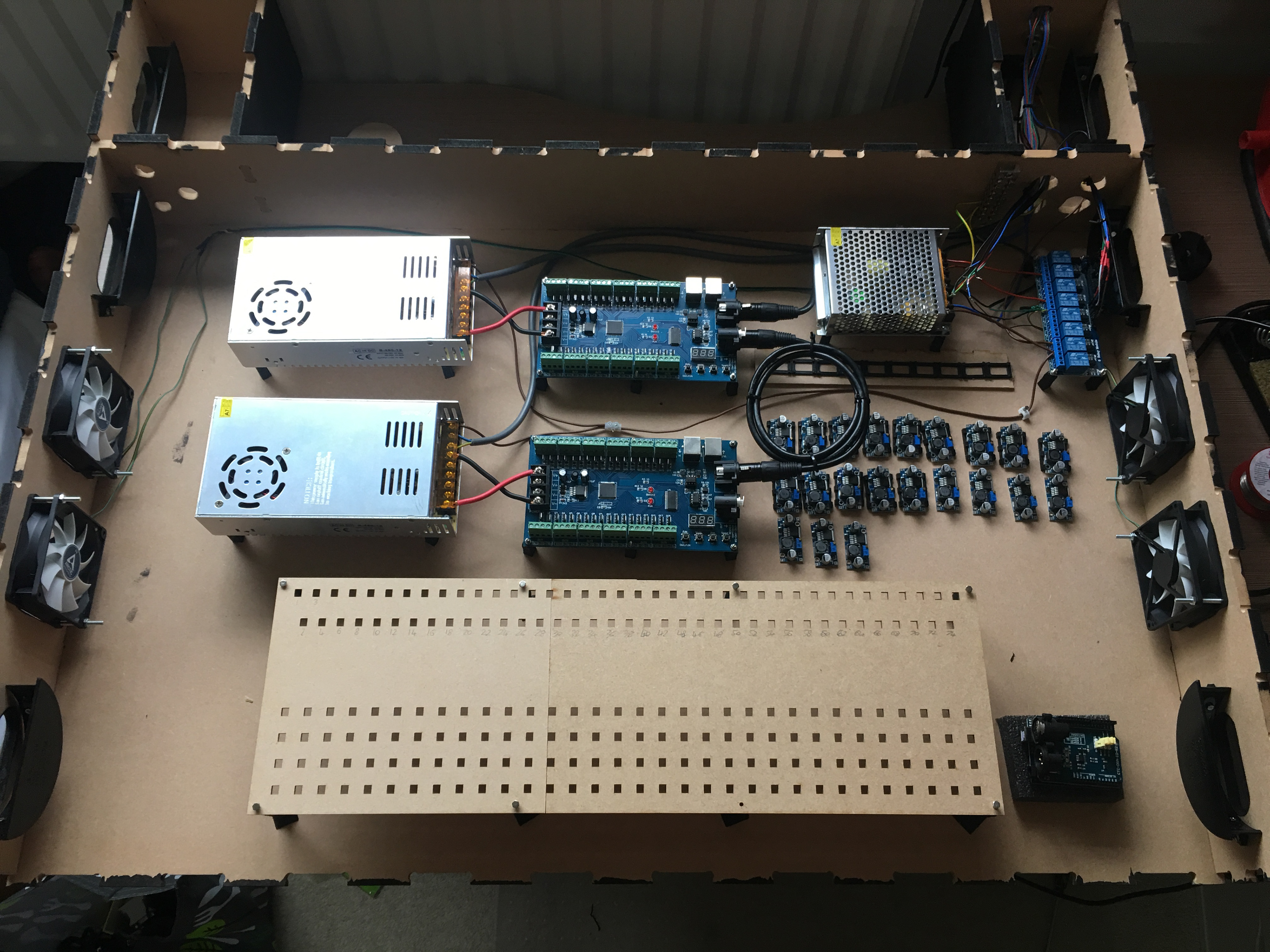

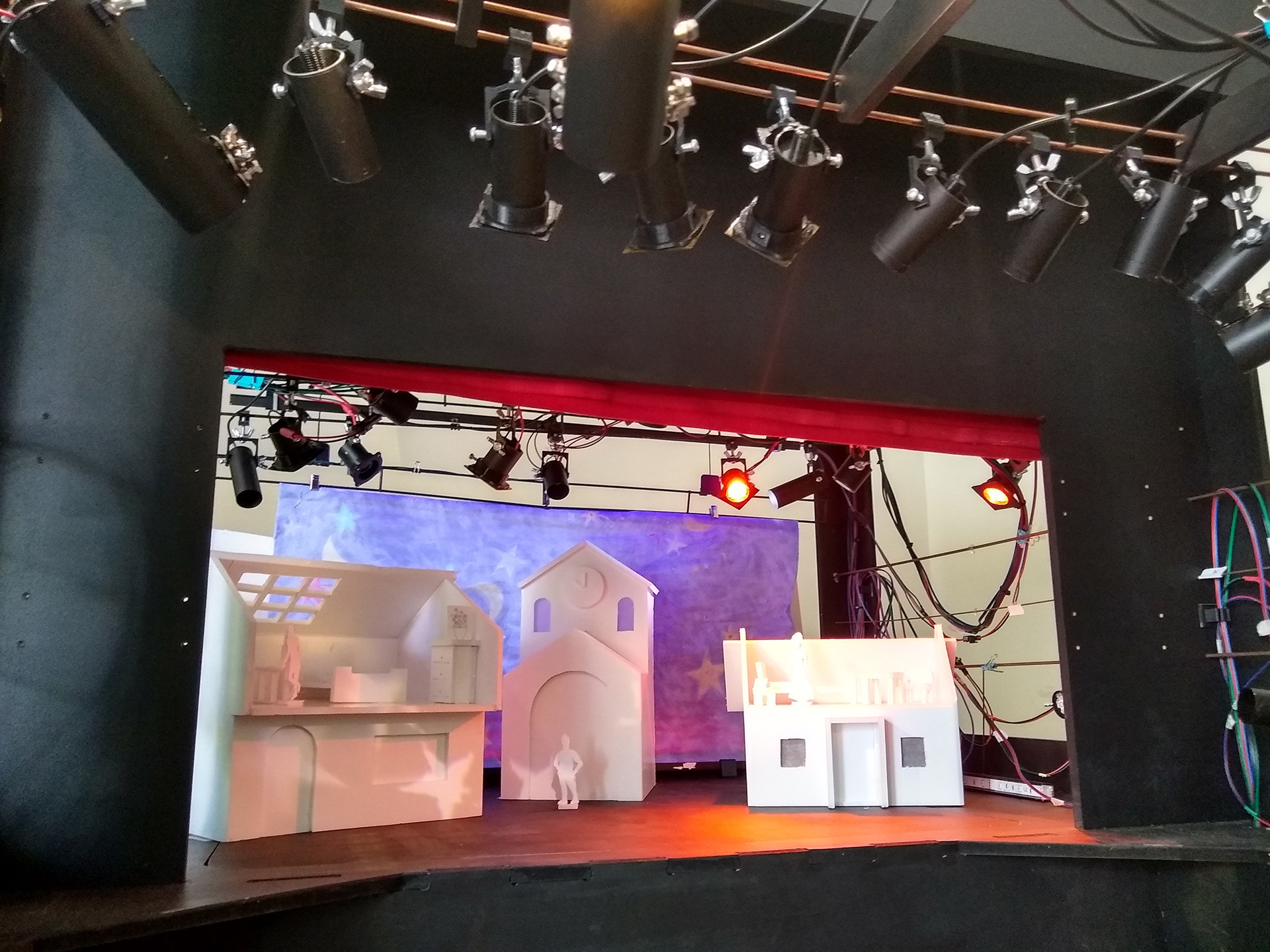

Functional Theatre Model

Fully functional 1:25 scale model theatre conceived as a technical theatre training tool and as a show planning and visualisation resource (when theatre access is impractical or restricted for professionals). I designed the structure, electrical/mechanical systems, and programming. I used MDF, CNC router, advanced electronics, stepper motors, DMX dimmers, 3W LEDs, spot welding and 3D printing of scaled theatre lights. Via DMX, the model can control up to 72 individual lights and the position/speed/acceleration of three fly bars. Foundation year final project (May 2018); exhibited at the Royal Academy of Engineering (Jul. 2019).

Function and Features

- This mini theatre replicates the technical lighting and mechanical set infrastructure of a real theatre

- The lighting in the tool can be easily controlled using any industry standard lighting console

- Custom designed and built a selection of scaled down theatre lighting fixtures

- The lights, gels, lenses, barn doors and gobos are replicated to scale to give the same beam effects as a full sized setting

- Lighting gel frames are magnetic to make it easy to change colours

- A built in patch panel under the stage demonstrates how power is distributed through a lighting rig

- Some lighting fixtures contain RGB LEDs to enable colour mixing

- Fly bars can be used to raise and lower set pieces into view.

- The control console can control the speed, acceleration and height of 4 bars individually.

- Internal air cooling system continually monitors temperature and turns on fans when necessary to keep the electronics cool

- I designed the model to be as fixable as a real theatre.

- Flybar motors can be moved up and down stage depending on set requirements

- Lighting can be moved wherever required

- The lighting in the tool can be easily controlled using any industry standard lighting console

- Custom designed and built a selection of scaled down theatre lighting fixtures

- The lights, gels, lenses, barn doors and gobos are replicated to scale to give the same beam effects as a full sized setting

- Lighting gel frames are magnetic to make it easy to change colours

- A built in patch panel under the stage demonstrates how power is distributed through a lighting rig

- Some lighting fixtures contain RGB LEDs to enable colour mixing

- Fly bars can be used to raise and lower set pieces into view.

- The control console can control the speed, acceleration and height of 4 bars individually.

- Internal air cooling system continually monitors temperature and turns on fans when necessary to keep the electronics cool

- I designed the model to be as fixable as a real theatre.

- Flybar motors can be moved up and down stage depending on set requirements

- Lighting can be moved wherever required

Research

- To better understand the workings of a large theatre I arranged a visit to The Curve Theatre in Leicester

- Personal behind the scenes tour

- Collected measurements and photos

- Personal behind the scenes tour

- Collected measurements and photos

Water Fall Table

A centre-piece functional office table/storage space with an integral water feature and RGB LED lights. I used plywood, marine plywood, acrylic and a water pump. AS Level Product Design Project (2016).

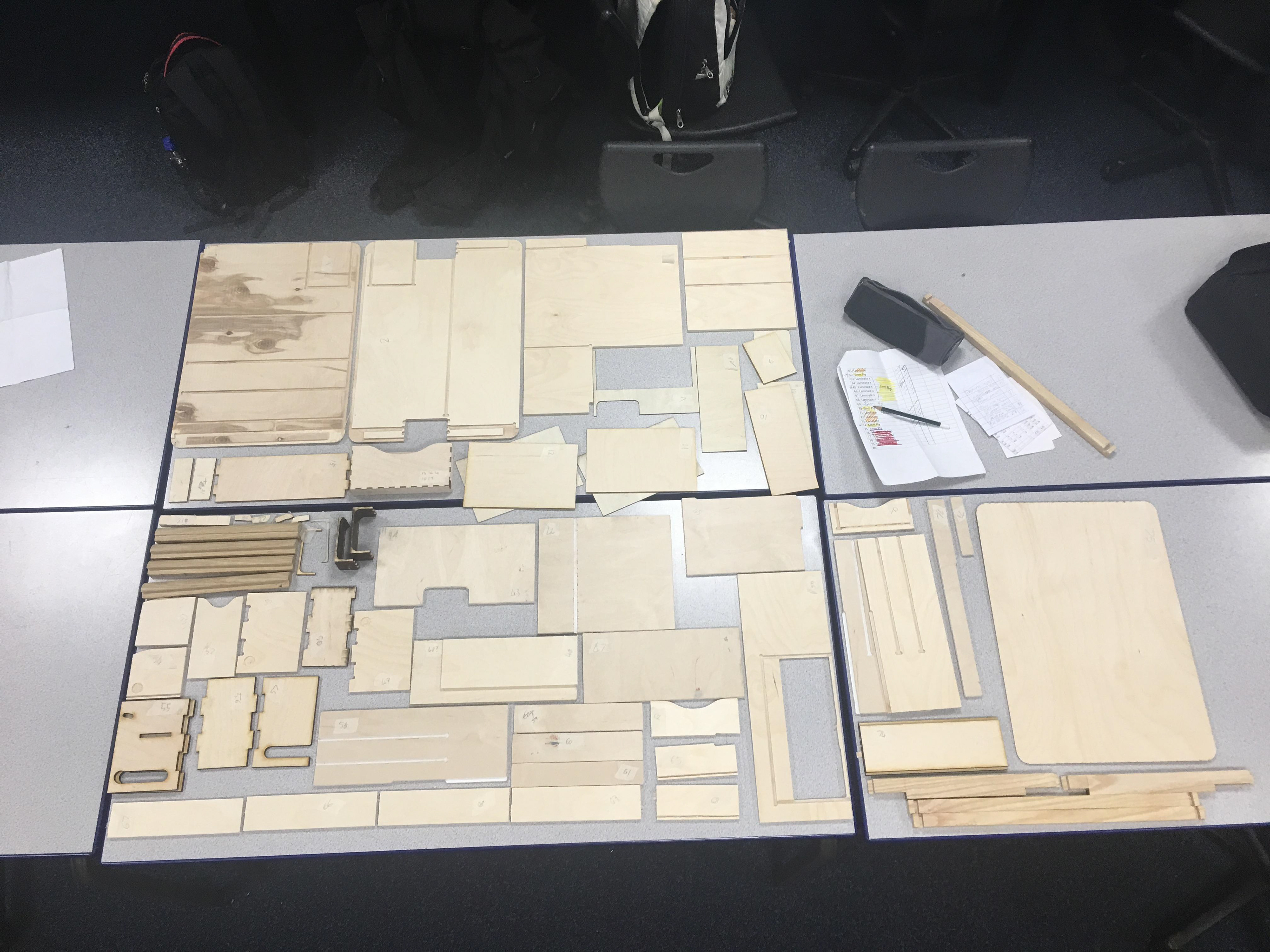

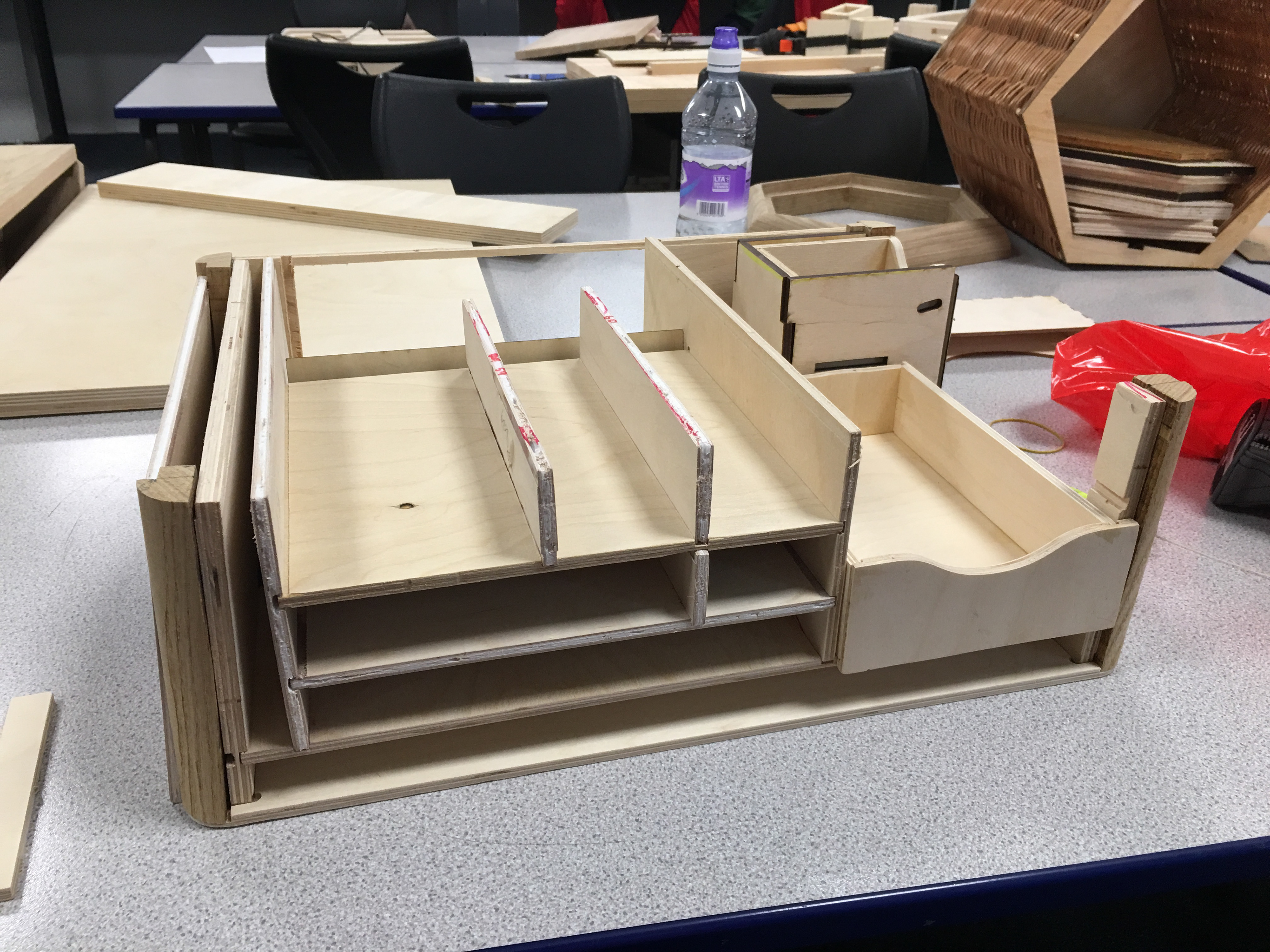

Laptop Portable Workstation Organiser

A portable laptop station and desk organiser. Designed for a businesswoman working from a home environment who requested speedy storage of all regularly used desk items and quick workstation transfer between different domestic locations. I used hardwood, MDF and custom lightweight laminated plywood to meet weight specifications. A Level Product Design Project (2017).