Modelmaking

I am a hard edge maker but being a modelmaking graduate, I am equipped with a diverse range of making skills including workshop machinery, hand tools, spray finishing, CAD, CAM and electronics. I am often working with wood and plastics and have an interest in resins and metal work.

Barley Hall's Great Chamber

Juhl's Eye Table

Windows 95 Desktop

Charlie Weasley Props

Taut's Glass Pavilion

Ullman Dynamics Seat

Sci fi Film Prop

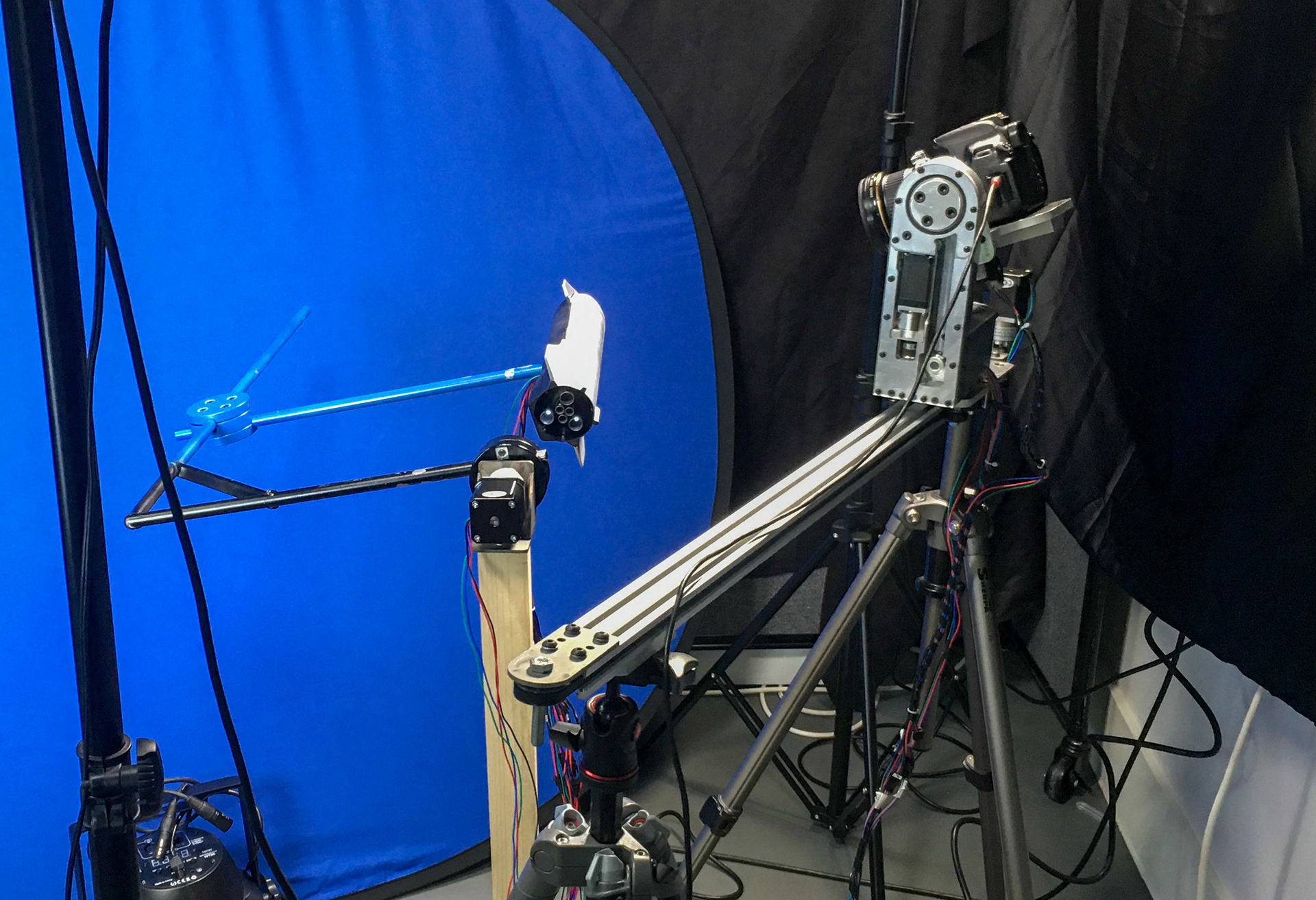

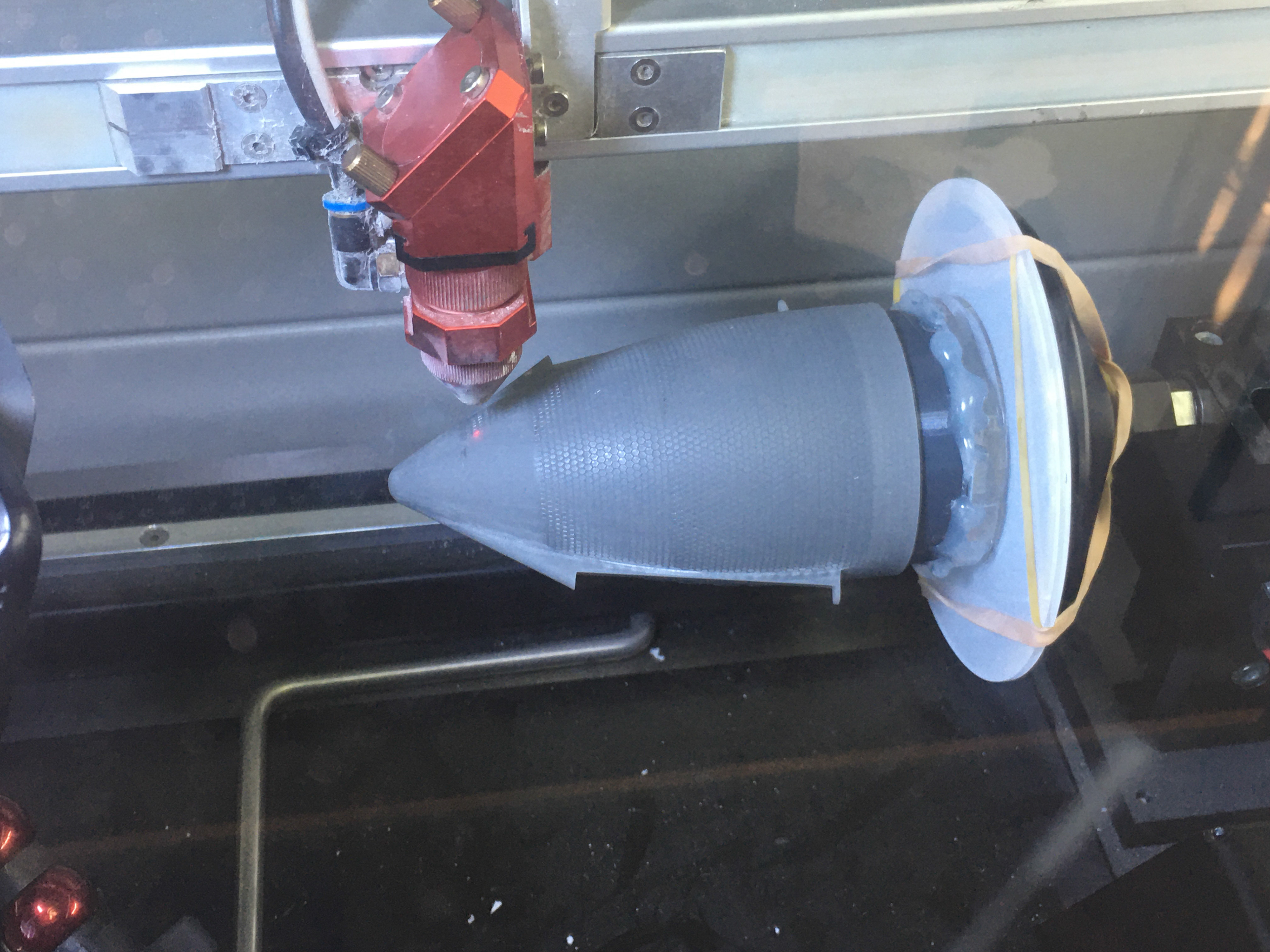

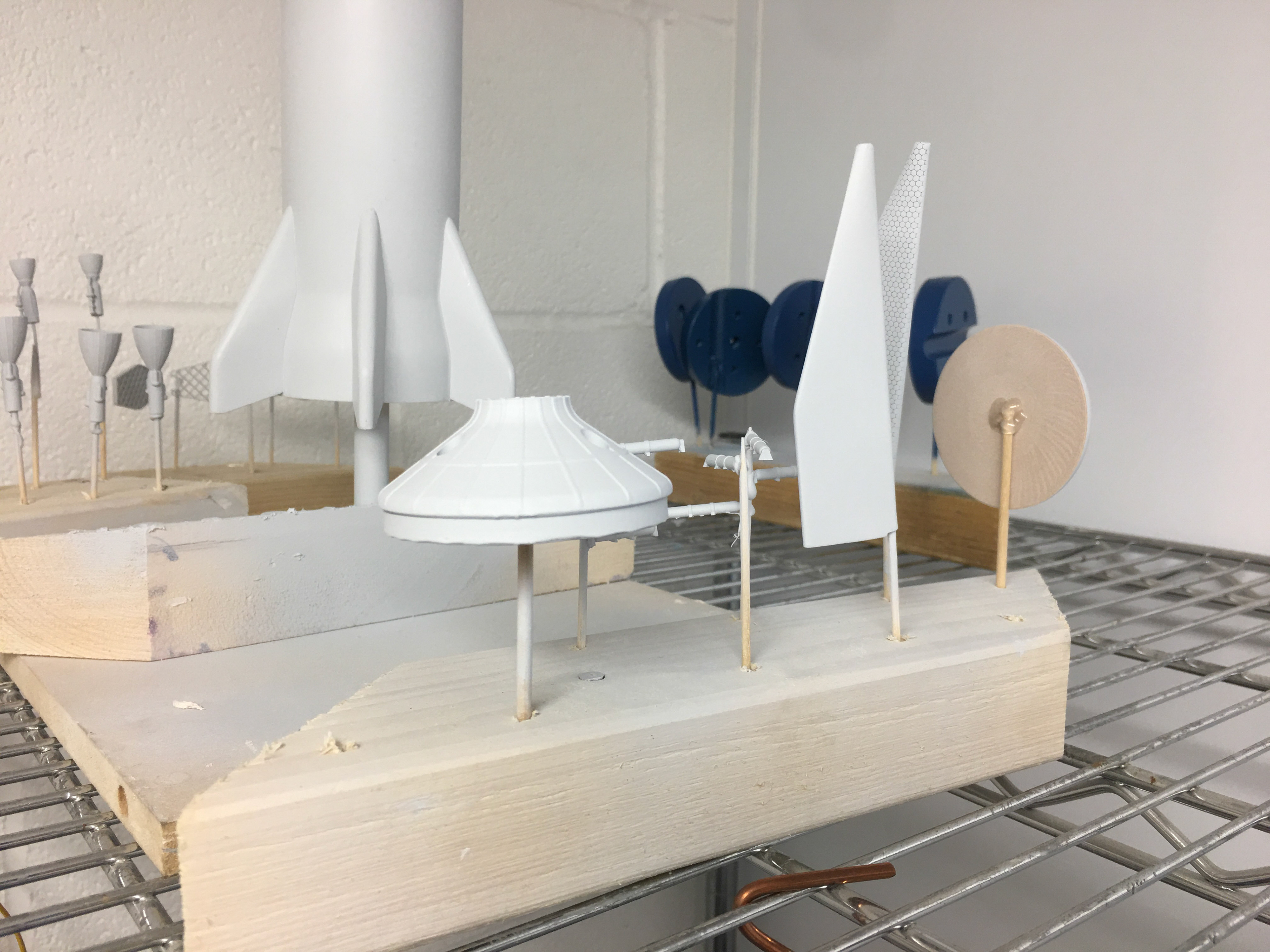

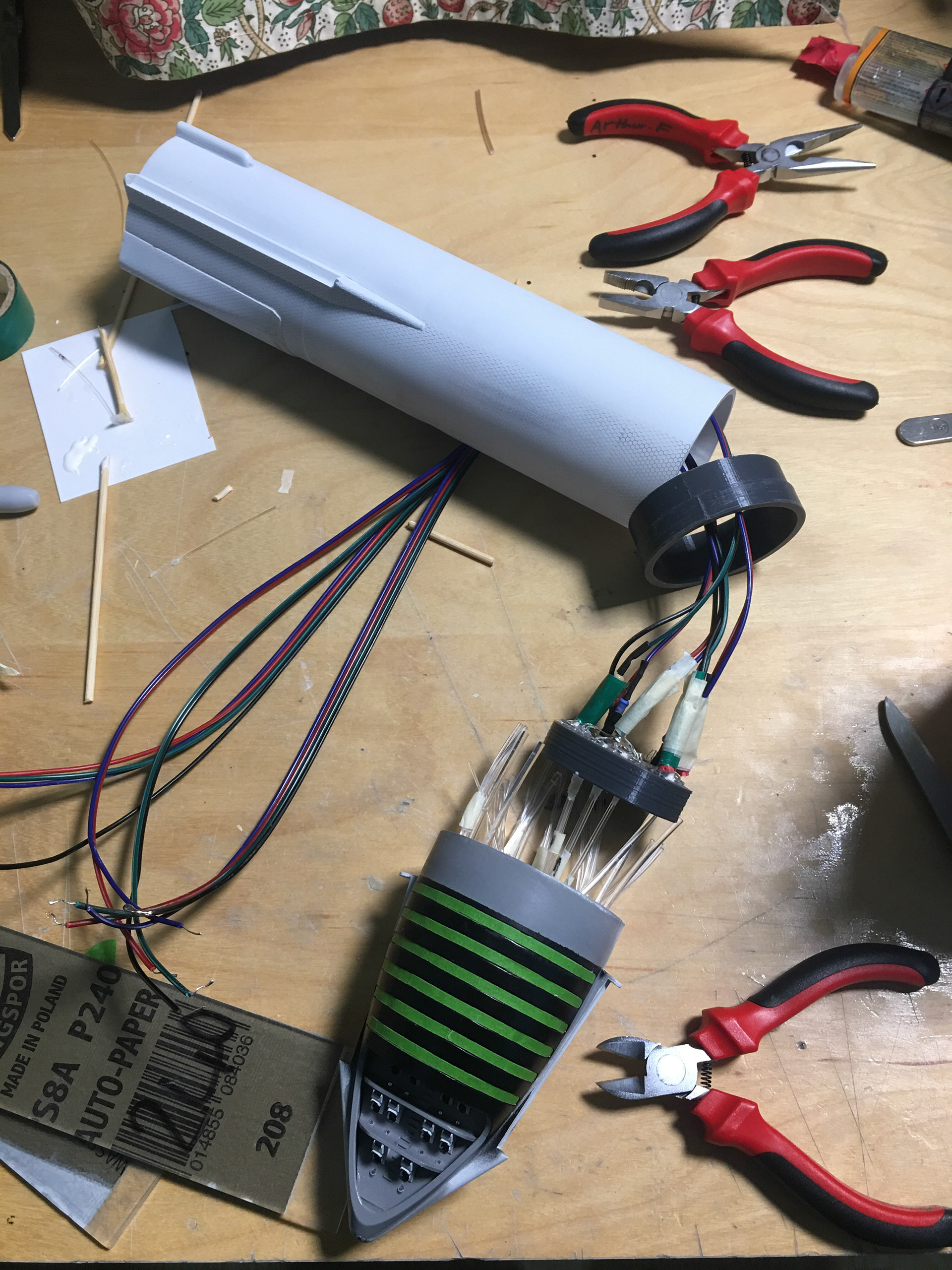

SpaceX Starship Scale Model for Motion Control Rig

As part of my 14-week (Feb-May 2021) final major project at university, I needed to make a scale model for use with a motion control system I was also designing. I chose to create a model of SpaceX's Starship. I used their computer-rendered marketing material as inspiration for the shots which the rig would create using the miniature. The idea for this project came while watching a behind-the-scenes documentary of Disney’s The Mandalorian which showed the original Star Wars filmmaking technique of motion control and miniatures - before the days of advanced CGI.

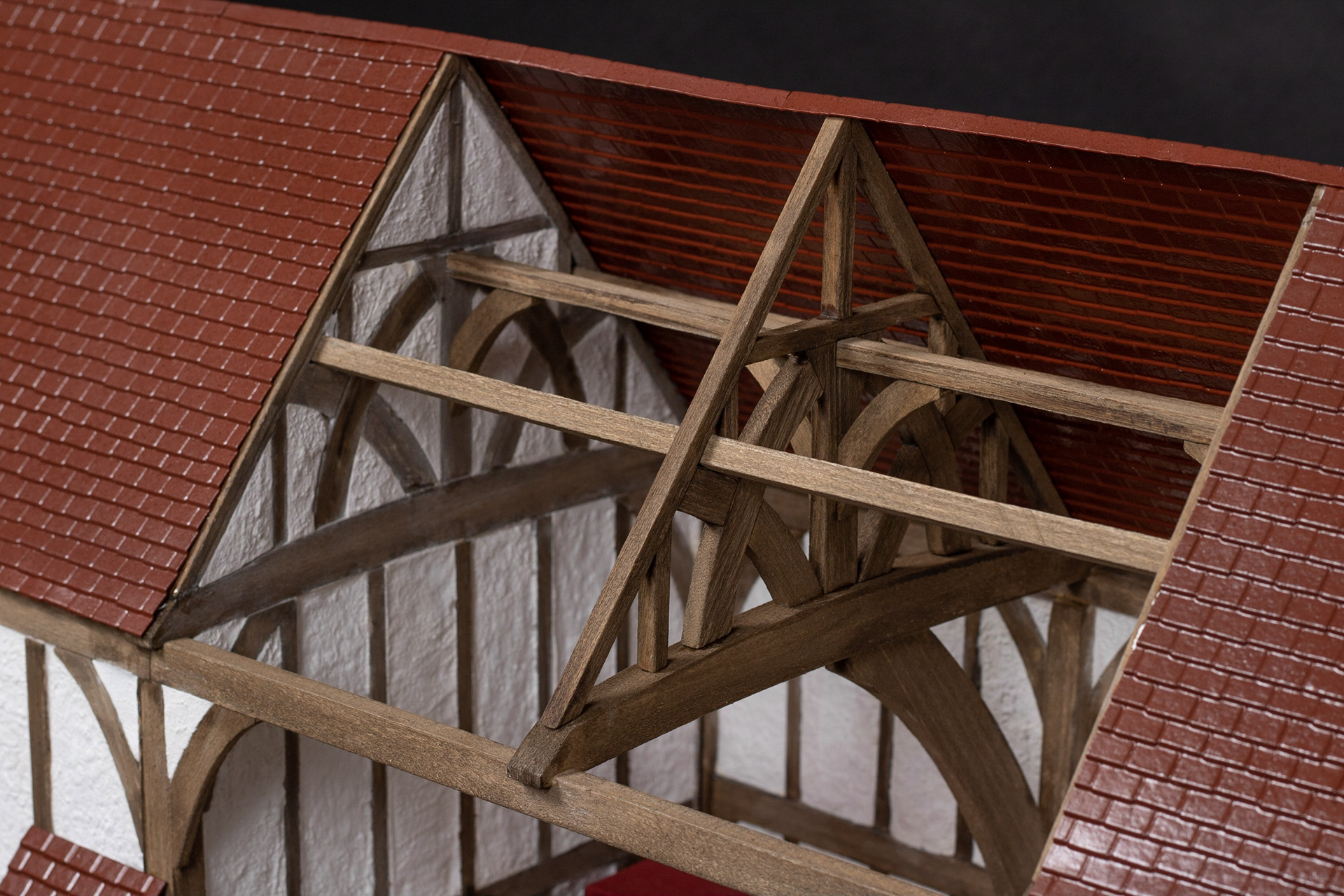

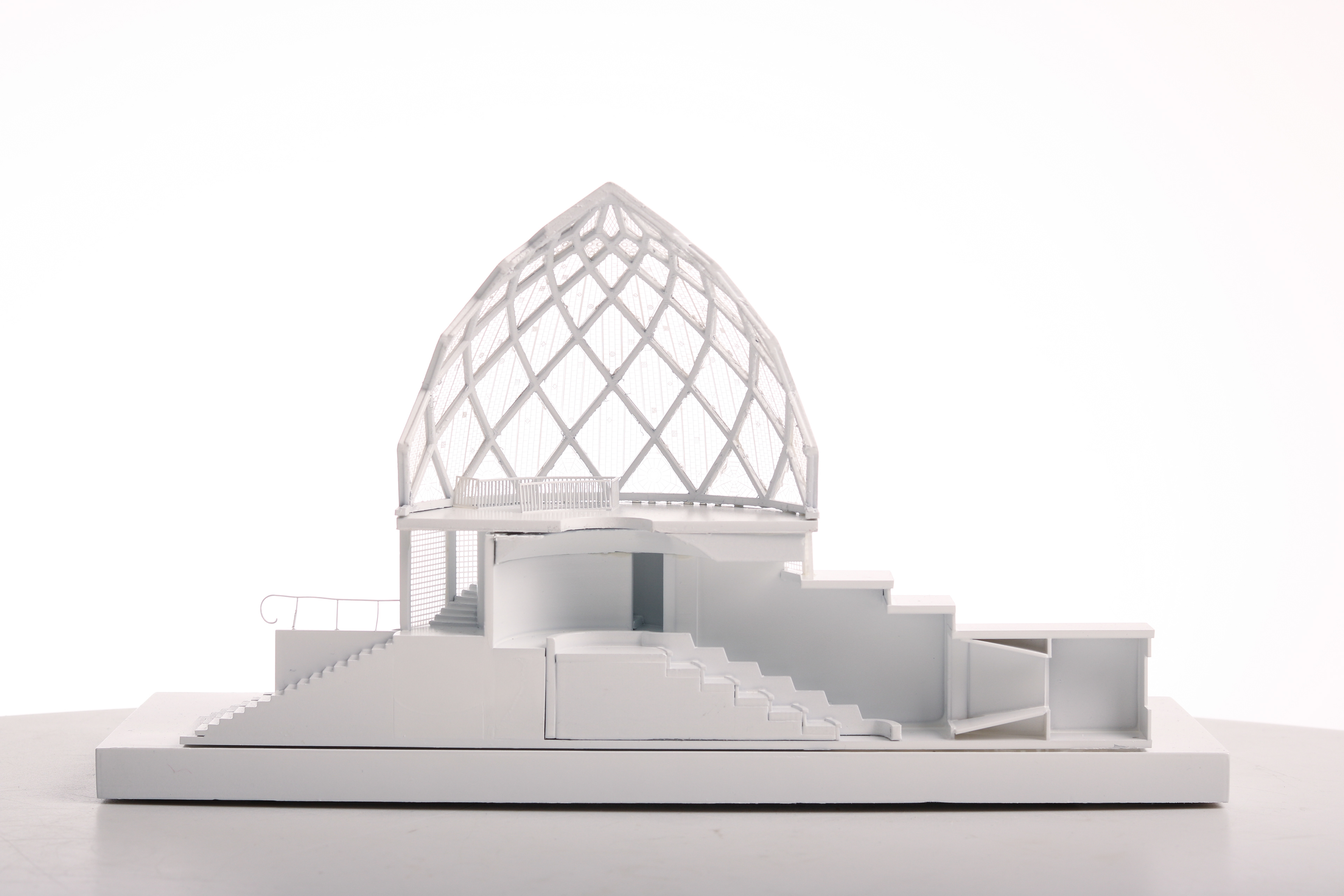

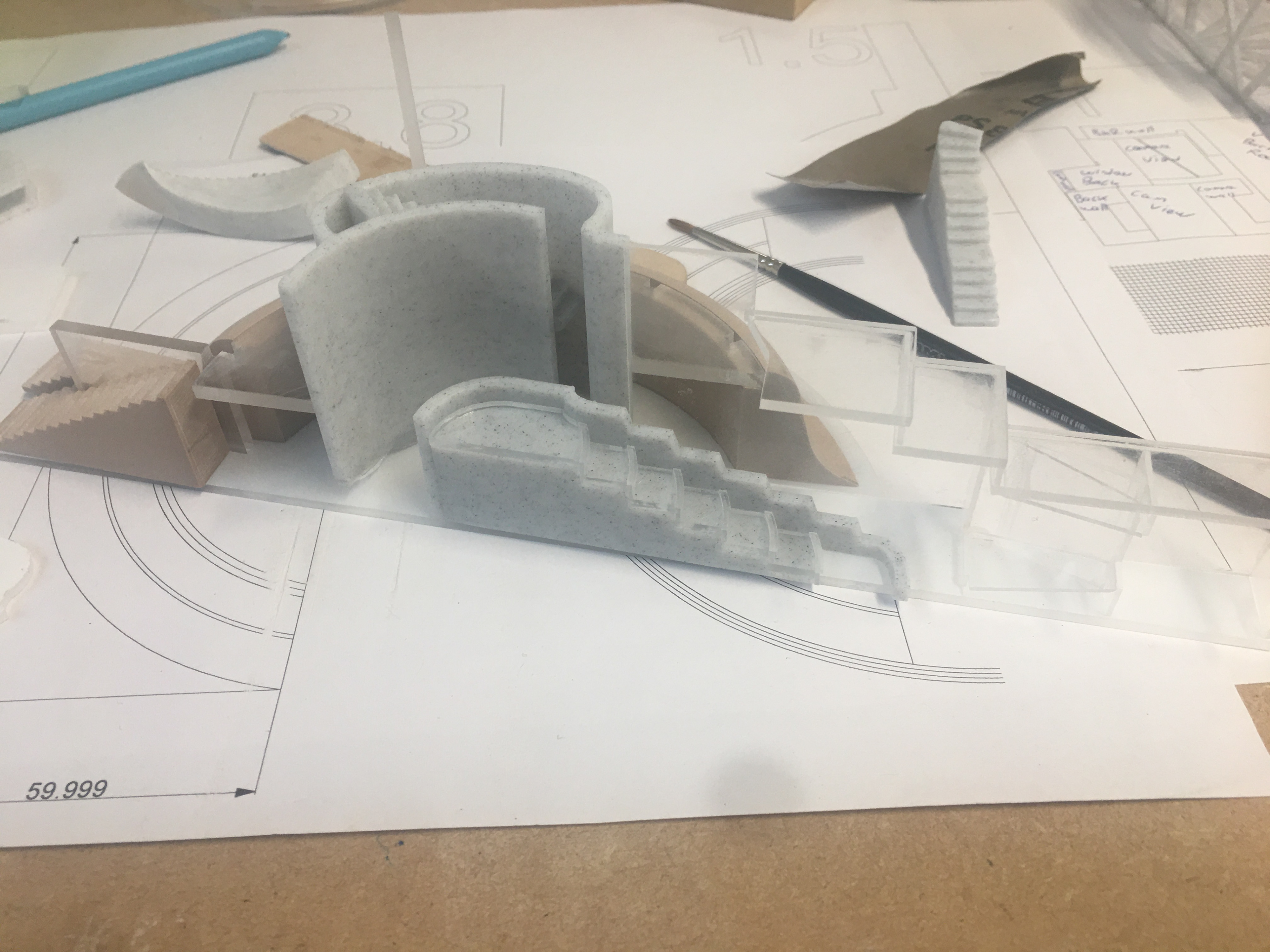

Jorvik - Barley Hall's Great Chamber

A final degree year external client-led live brief. Working directly with the Head of Interpretation and Engagement, Jorvik Centre, UK, I specified and built a 1:24 scale model of the Barley Hall’s Great Chamber. I worked in bass wood, plaster, styrene, acrylic and MDF using laser cutting, 3D-printing, vacuum forming and spray finishing. The 7-week project (Oct-Dec 2020) required key professional skills of communication and project/time management.

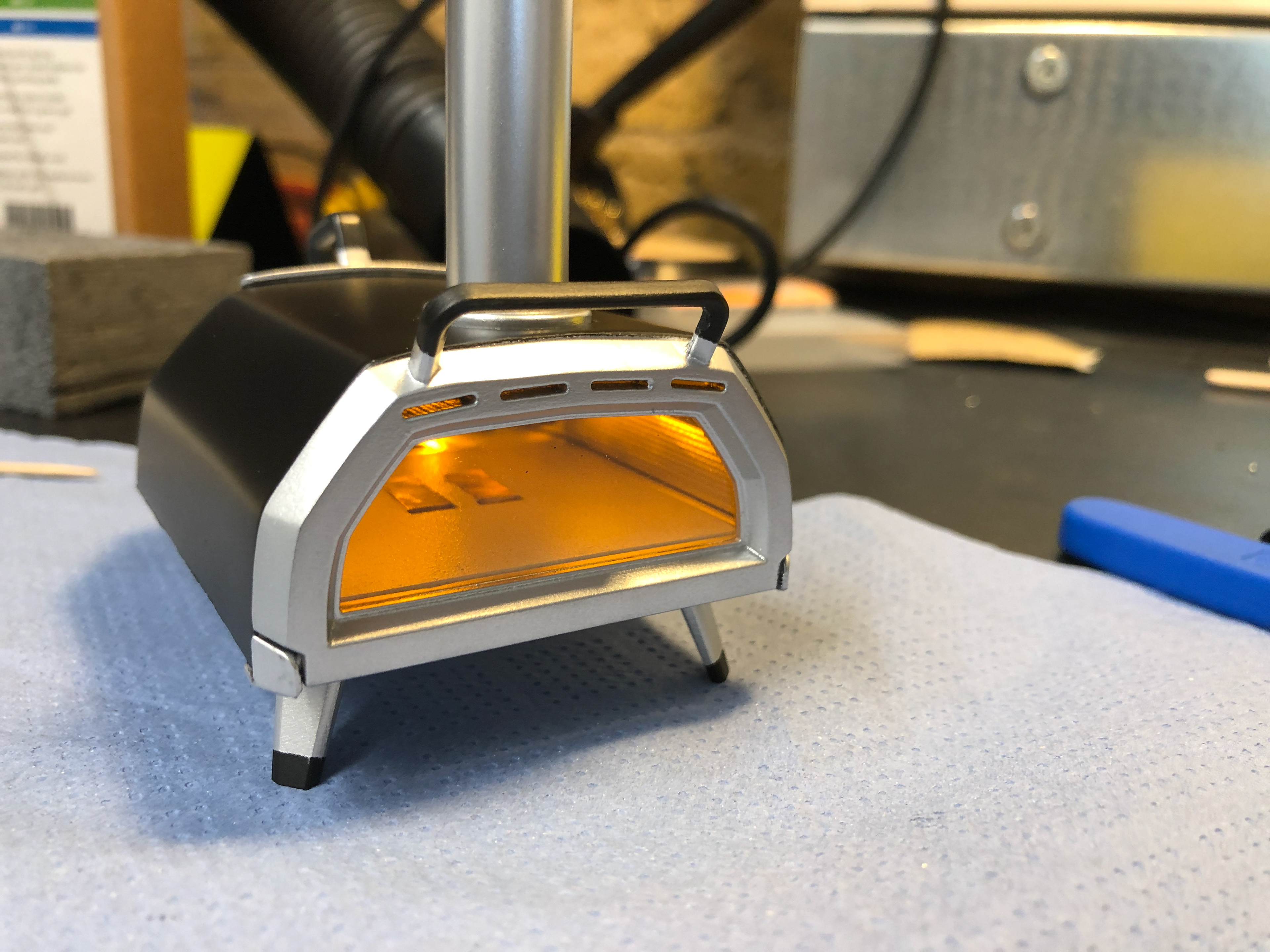

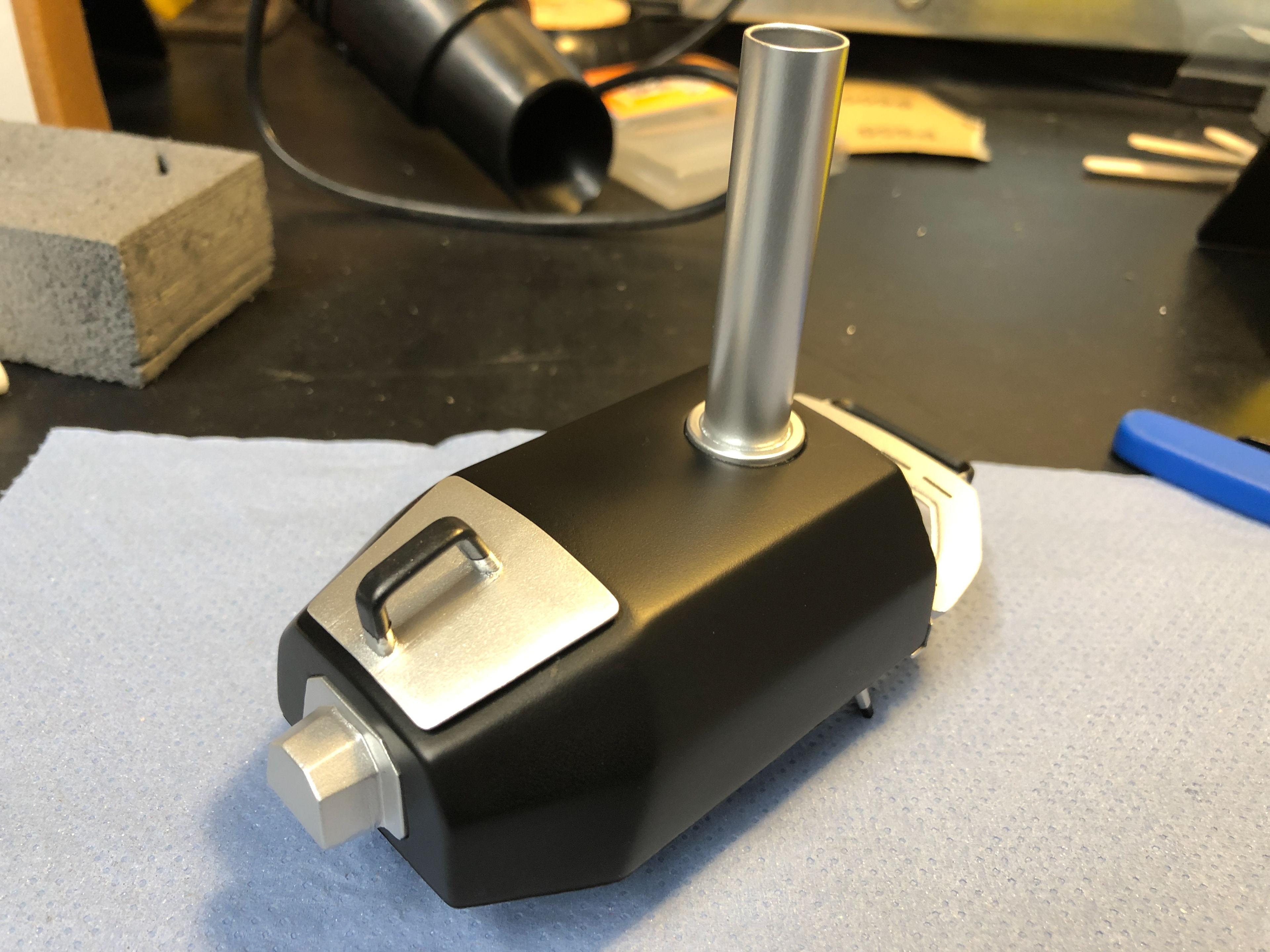

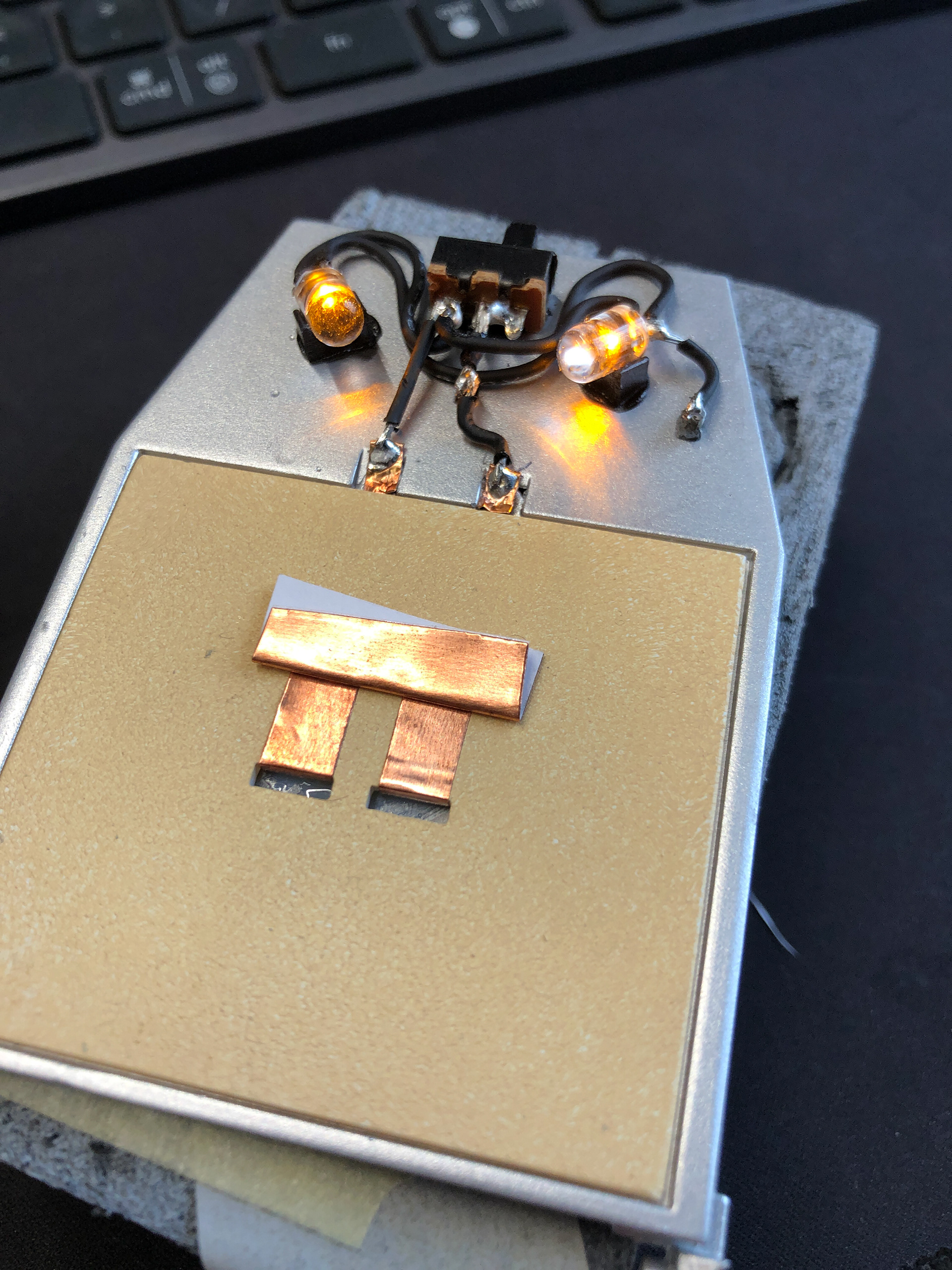

1:6 Scale Ooni Pizza Oven Model

As a side project last year I build this mini light-up pizza oven. The light activates in one of two ways; a switch at the back with a magnetic cover, or placing a pizza inside which bridges the circuit and causes the lights to turn on.

Charlie Weasley Props

Design and build of original artefacts for realistic purposes. I selected a minor Harry Potter character to stimulate the visualisation and creation of props absent from the narrative. I used PLA, acrylic tubing, acrylic and spray can paints, 3D printing, paint and texture finishes. All work was completed without access to university workshop facilities due to the 2020 lockdown. Second degree year final project, 6 weeks (May 2020).

Hebridean Black Dragon Scale

Dragon Syrine

Charlie's Wand

Dragon Syringe Diagram

Windows 95 Desktop

Visual pun/play on words. I modelled a PC 'desktop' as an actual desktop and made Windows 95/98 icons as physical objects. It was built from acrylic, styrene, chemiwood and used 3D printing, laser cutting and spray finishing. Second degree year project, 5 weeks (Mar. 2020).

Windows 95 Desktop

Windows 95 Desktop

Windows 95 Desktop

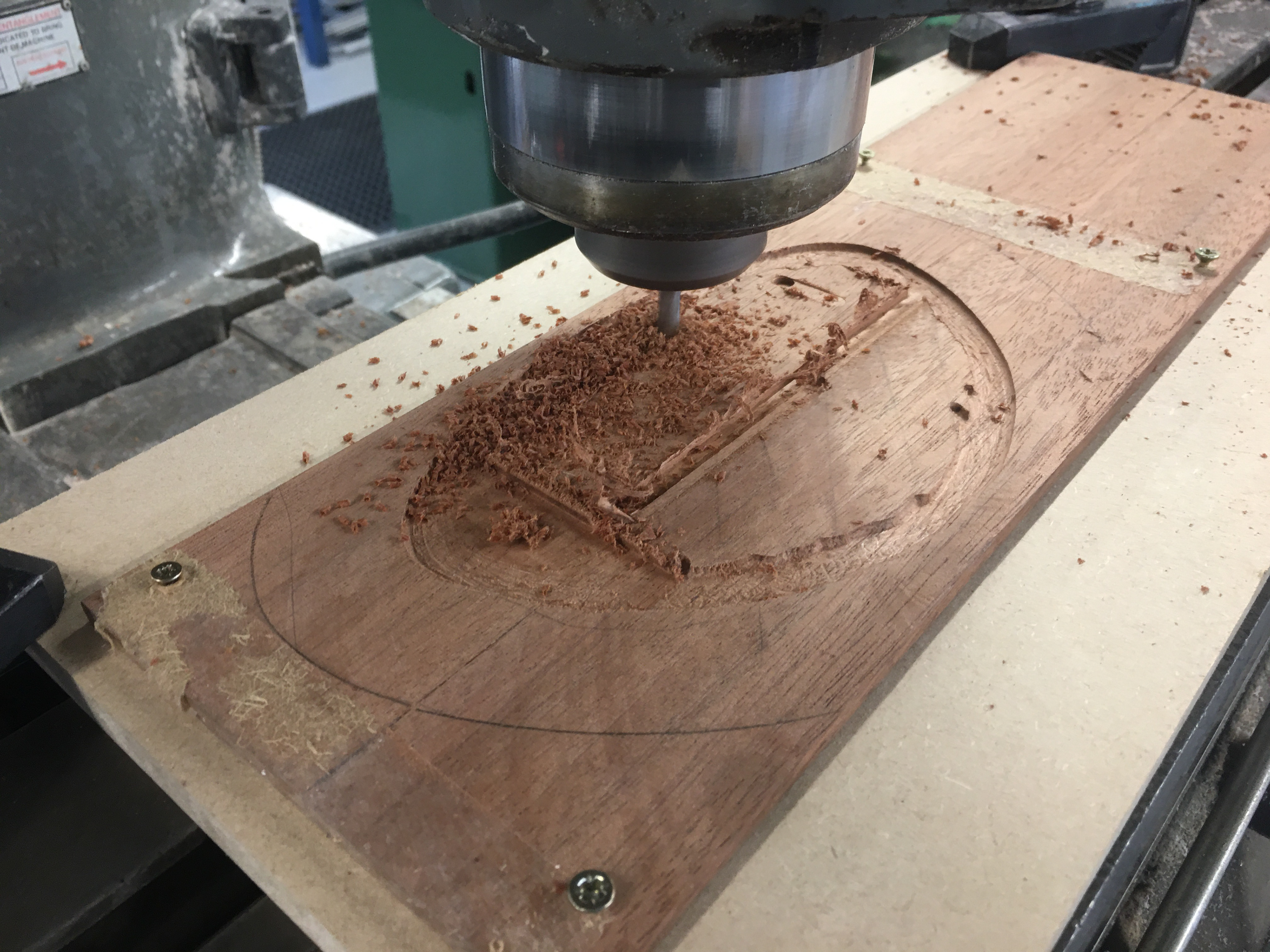

Finn Juhl's Eye Table

Project specifically requiring non-digital design and manufacture. I researched the design and construction of Finn Juhl’s iconic Eye Table, developed sketches and scale drawings by hand, then built a 1:6 scale model. I employed mahogany and iroko wood using a lathe, mill and hand router, finishing with sanding and beeswax. Second degree year project, 4 weeks (Dec. 2019).

Juhl's Eye Table

Juhl's Eye Table

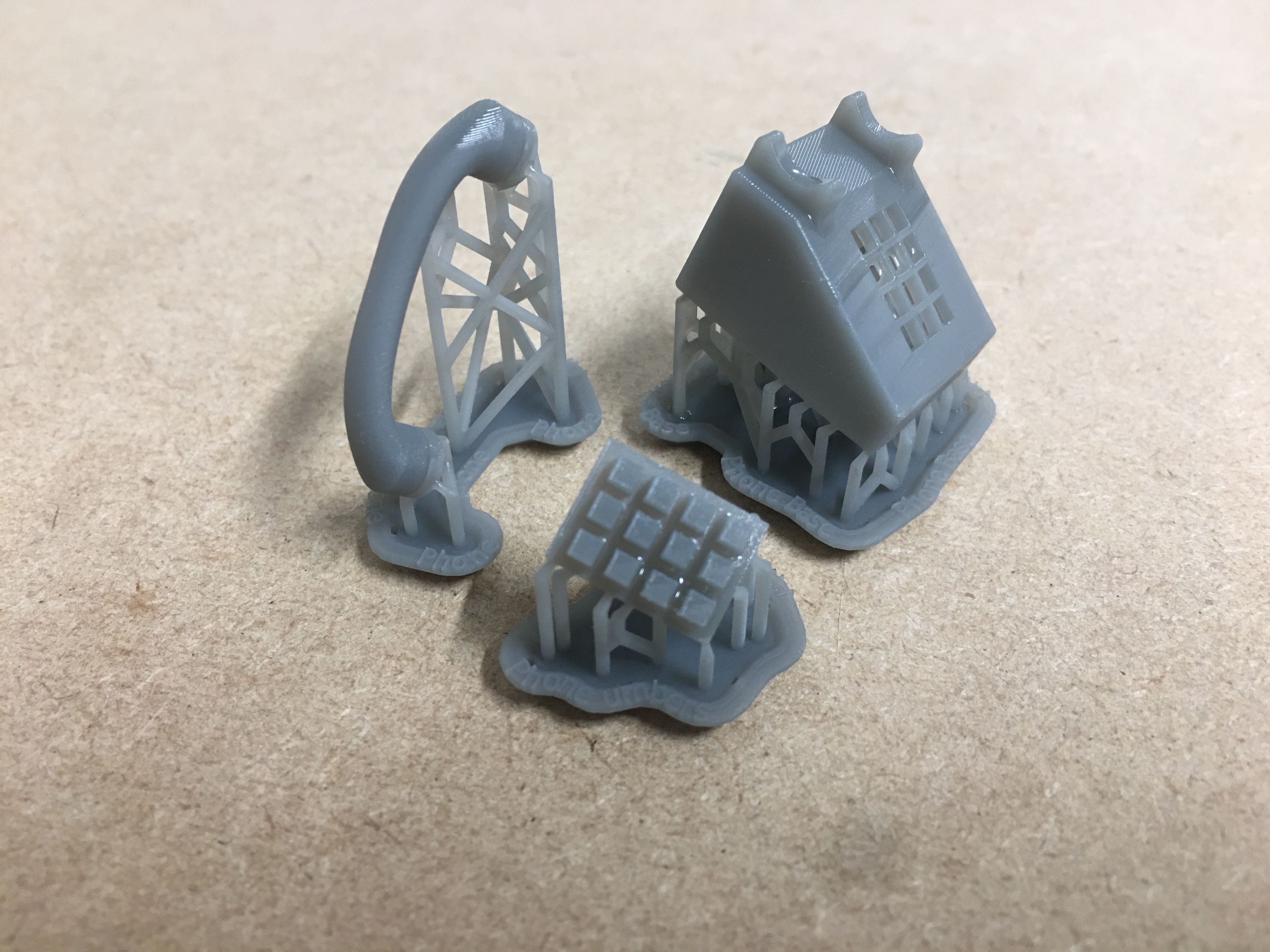

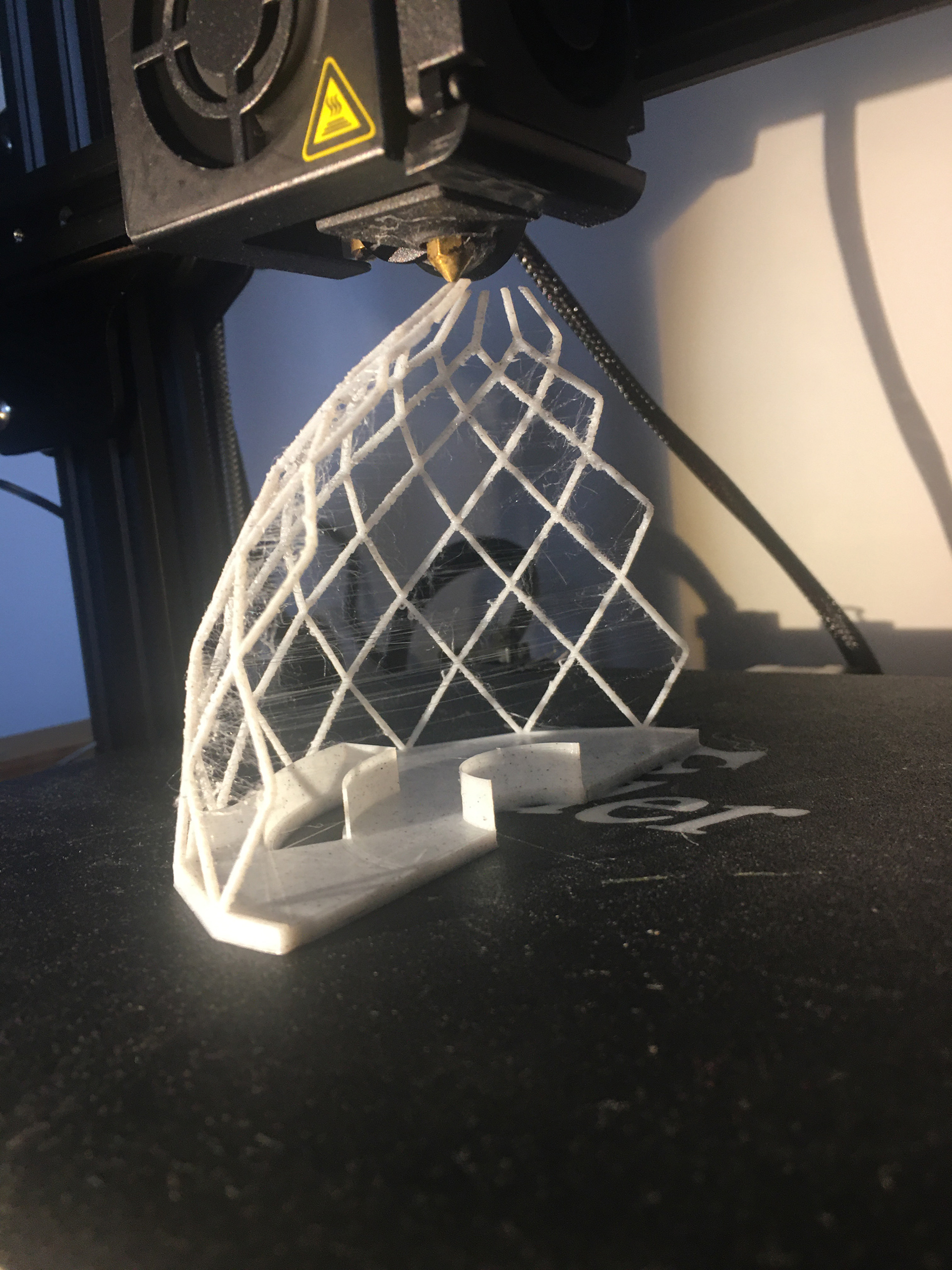

Bruno Taut's Glass Pavilion

Project exploring the types and conventions within architectural modelling. I researched, designed and built a 1:200 scale model of Bruno Taut’s famous Glass Pavilion. I used MDF, chemiwood, styrene, acrylic and FDM 3D printed parts. Second degree year project, 4 weeks (Oct. 2020).

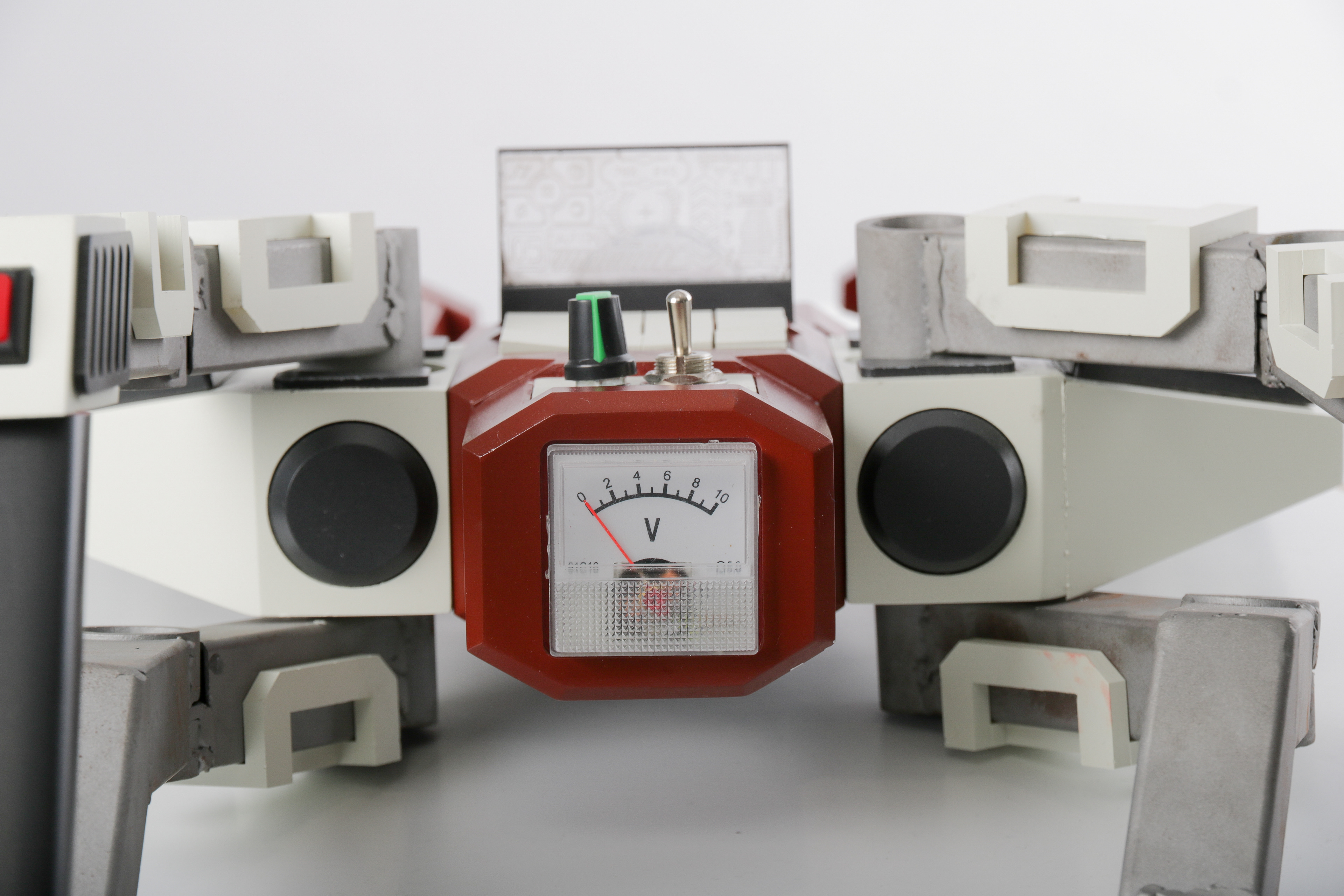

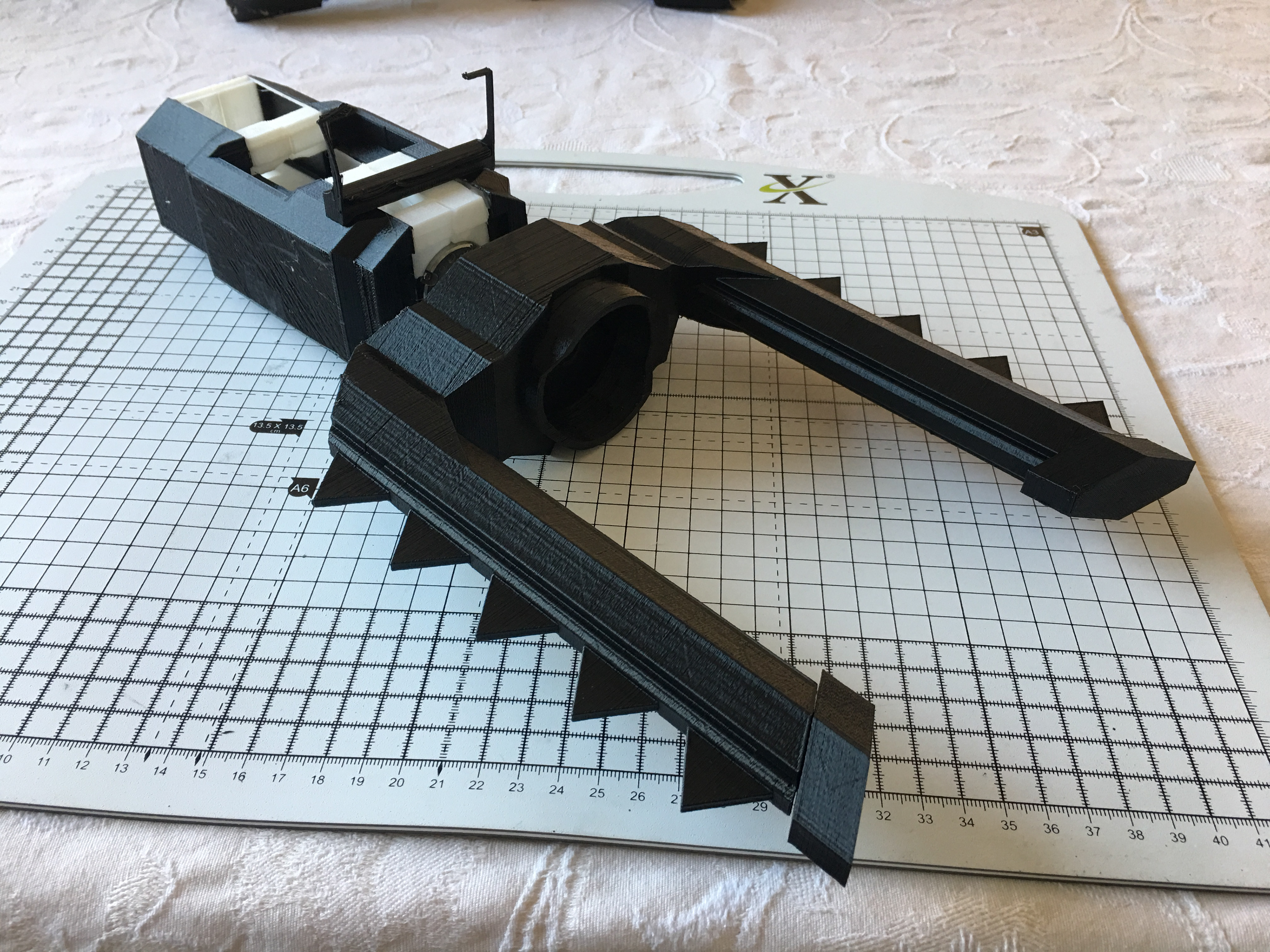

Sci fi Film Prop

Designed and built a sci-fi film prop (with a functional mechanism) from an issued brief. I designed a fictional asteroid mining tool in CAD and then built it from chemiwood, acrylic, styrene, acrylic tube and steel. I used laser cutting, welding and basic electronics. It has functioning switches, lights, analogue readouts and a motor. First degree year project, 6 weeks (May 2019)

Prototype

Prototype

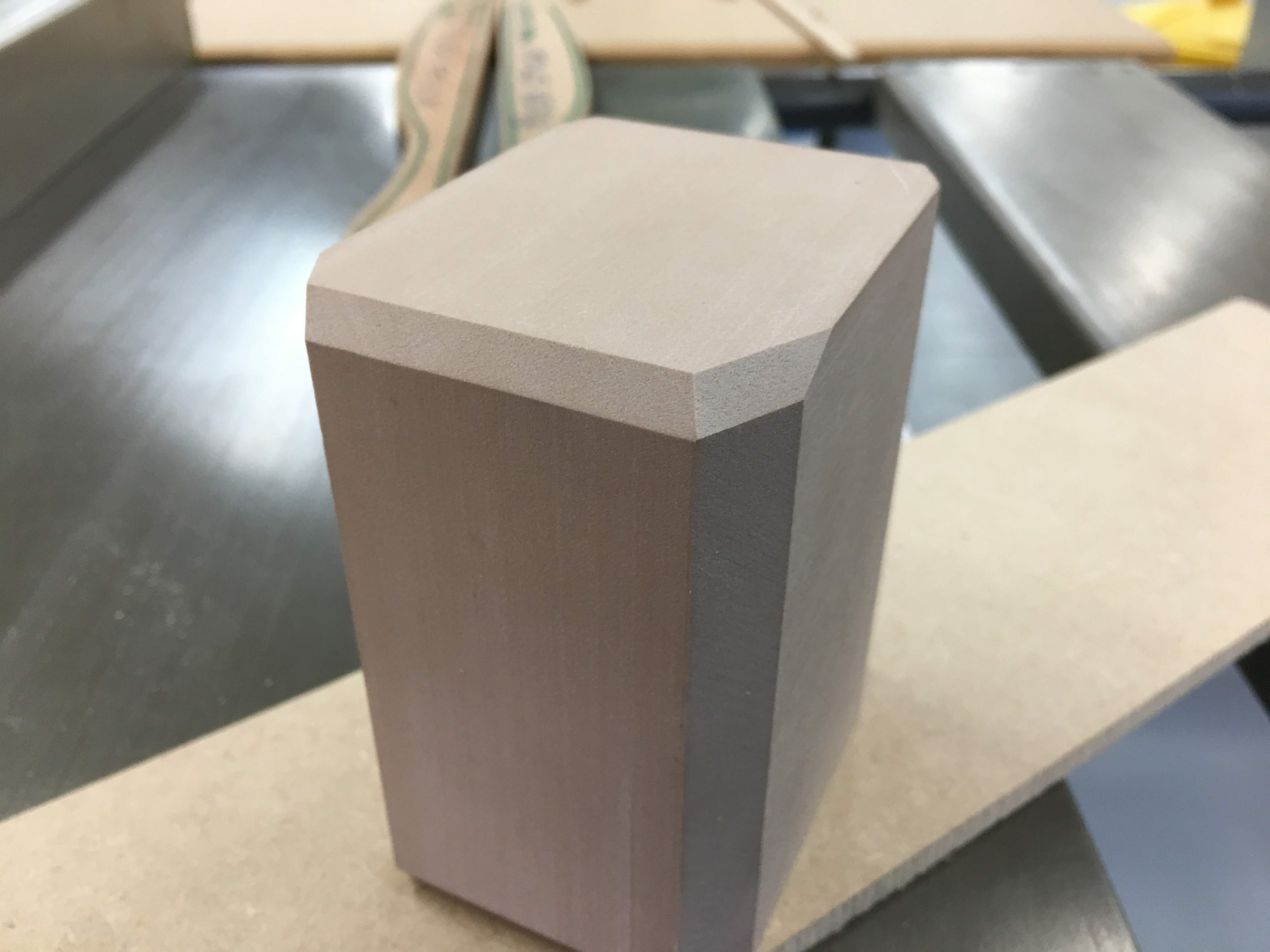

Ullman Dynamics Suspension Boat Seat

Project focussing on the conventions of product modelling. Working from a supplied technical drawing of an Ullman Dynamics Atlantic seat I built a 1:6 scale model. At 260mm tall it is made from model board, styrene, acrylic, faux leather and fast cast resin. I used heat bending, spray finishing, lathe turning, moulding and casting. First degree year project, 6 weeks (Jan. 2019).